ETH Zurich students have developed a laser powder bed fusion machine that can process multiple metals at once.

The system follows a circular tool path, allowing it to print round components, and will open up new possibilities for aerospace and industry, according to ETH Zurich. A patent application has been filed.

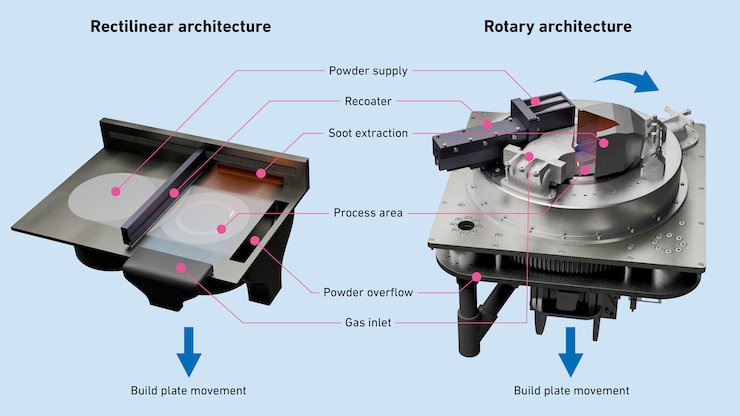

With the application of 3D printing in the rocket manufacturing industry growing, students at ETH Zurich sought to build a high-speed and multi-material printer that can process several metals simultaneously and without process dead time. It achieves this by rotating the powder deposition and gas flow nozzles while it prints.

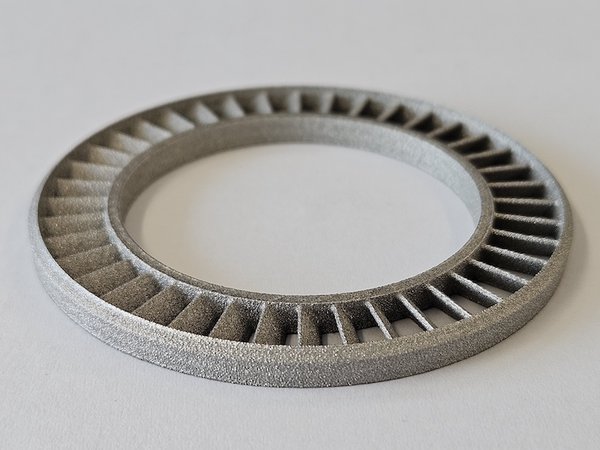

The machine was developed by six Bacherlor’s students in their fifth and sixth semesters in the ETH Advanced Manufacturing Lab under the guidance of Professor Markus Bambach and Senior Scientist Michael Tucker as part of the Focus Project RAPTURE. Over the course of nine months, the machine has been built and tested, with the students confident the platform could facilitate the printing of ‘approximately cylindrical geometries,’ such as rocket nozzles and turbomachinery.

ETH Zurich was commissioned to develop the machine by ARIS, the Swiss Academic Space Initiative, which is working to reach the Kármán Line – an altitude of 100 kilometres, which is the internationally recognised boundary of space. ARIS set ETH the challenge of developing bi-liquid-fuelled rocket nozzles. Because of the intense heat and pressure they need to withstand, rocket nozzles are said to perform better when they’re manufactured with multiple metals – the interior being made up of heat-conducting copper with integrated cooling channels, for example, and their exterior of a heat-resistant nickel alloy.

A multi-material metal laser powder bed fusion technology, however, has been ‘too complex and too expensive’, according to Tucker. Now, though, ETH Zurich believe have a solution. With a rotating platform that enables high-speed printing, the RAPTURE machine works non-stop, applying and fusing powder simultaneously to reduce the manufacturing for cylindrical components by ‘more than two-thirds.’ ETH says the rotating machine can process two different metals in a single operation, with the process only depositing material where it is needed and featuring a mechanism that blows inert gas over the area where the powder is fused. Components therefore don’t oxidise as they’re being printed, with ETH also suggesting soot, spatter and other by-products are also extracted via an outlet.

During the development of the machine, the students are said to have overcome several process challenges, including the synchronisation of the scanning laser with the rotation of the gas inlet and powder supply, and procurement challenges. Since many of the parts required for the machine were not commercially available, such as a rotatable connection for the gas inlet and a system that automatically refills the powder during operation, the team developed their own.

So far, the students have manufactured prototype parts with a diameter of up to 20 centimetres and is looking to scale the process to higher speeds and larger diameters. There is a belief that, in addition to rocket nozzles, the machine will also be able to additively manufacture electric motors, gas turbines and other applications where ‘ring-shaped geometries are the norm.’

The group is seeking industry collaborations to further develop the technology.