Global imaging and print company, Ricoh is expanding its 3D printing capabilities in partnership with chemical giant, Solvay, to push the use of Sinterline Technyl PA6 in additive manufacturing (AM).

The two companies are working together to market Ricoh’s first AM system, the RICOH AM S5500P’s with Sinterline Technyl PA6 GB (Glass Beads) high performance powders, to grow the range of AM applications available to their customers.

The selective laser sintering machine, which went on display to the public for the first time at formnext powered by tct in 2015, is the largest machine capable of 3D printing with Sinterline Technyl PA6GB (the RICOH AM S5500P features a build volume of 500mm x 500mm x 500mm) and is one of only a handful of machines with the ability to print higher temperature polyamides.

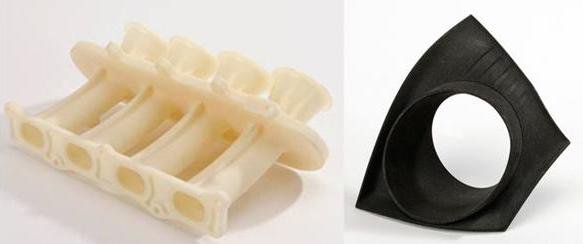

Sinterline Technyl Powders deliver strong mechanical, thermal and chemical performance and provide good flowability for efficient sintering. Sinterline Technyl PA6 GB offers significant advantage in the automotive and aerospace industries and the combination of the two is set to

give manufacturers the freedom to create short-runs and functional prototypes with performance comparable to PA6 injection moulded parts.

Greg Plowman, Director, European AM Business Group, Ricoh Europe, commented: “The potential of PA6 GB allows us to evolve the range of applications the RICOH AM S5500P can offer to our customers. The intrinsic features of PA6 powders allow functional prototyping and are ideal for small series applications where part performance and durability are essential criteria.”

Ralph Rissé, Sinterline Global Business Development Manager, Solvay Performance Polyamides, added: “Today, speeding up the development process of new applications across a wide range of industries, especially automotive, is crucial. The rapid prototyping of demanding parts that are closer to the final materials used for serial production provides OEMs and tiers an overwhelming design advantage when facing global competition to get products to market.”