3D scanning and robotics are real buzz words in the technology market at present and Breuckmann's latest 3D release combines both.

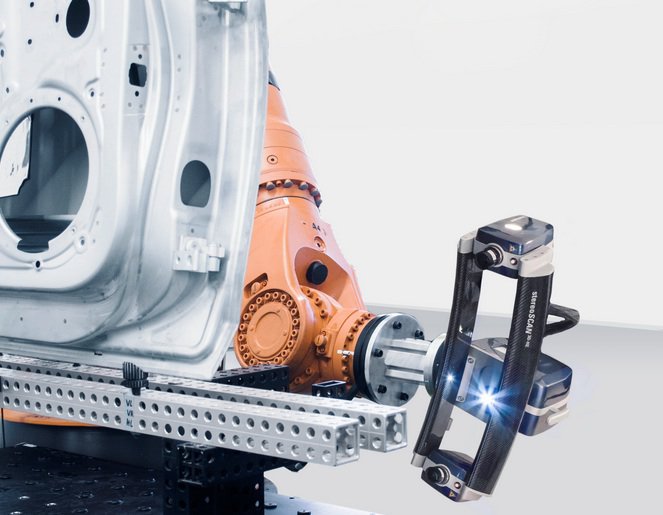

This week, the inspection company - which was acquired by leading optical camera-based 3D measurement specialist AICON 3D Systems in 2012 - has unveiled the Breuckmann stereoSCAN.

The stereoSCAN has been built especially to inspect large components with the highest levels of precision and reliability using a robotic arm.

Using white light scanning technology, the stereoSCAN captures minute deviations and delicate structures with the highest-possible accuracy (<0.1 mm). The 3D scanning system captures the entire surface of the component, as opposed to coordinate measuring devices, which touch on single points on an object.

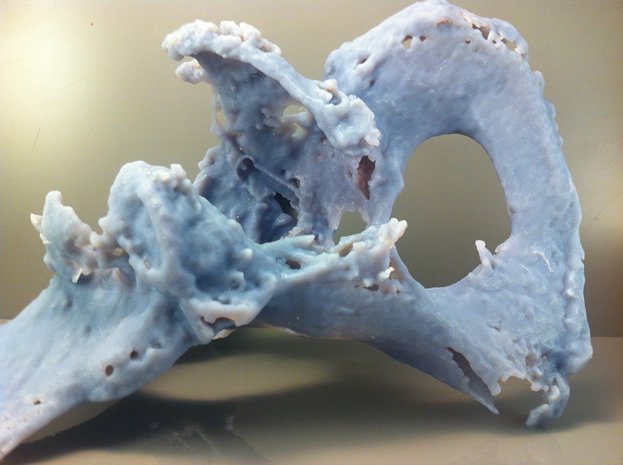

The result of this advanced imaging technique is a higher density of information. The user gets a precise 3D image of the object they are scanning, with a colour map indicating deviations from the CAD data.

The new stereoSCAN R16 3D scanner offers the highest sensor resolution availabke on the market and the device features two 16-megapixel cameras offering what the company calls "an unprecedented detail resolution and an accuracy previously only known from coordinate measuring machines".

As a result, the stereoSCAN 3D scanner is ideal for automated inspection and quality and production control.