Essentium has announced the launch of a polycarbonate (PC) 3D printing material that is able to withstand cold temperatures as low as -60°C without cracking.

The Essentium Altitude material has been designed for outdoor use and is said to be suitable for a wide range of applications that require extreme cold, ultraviolet and flame resistance.

Essentium has noted drones, drone bodies, outdoor housing, panel covers, electrical housings, electrical line protections, and outdoor maintenance components as potential applications for the new material.

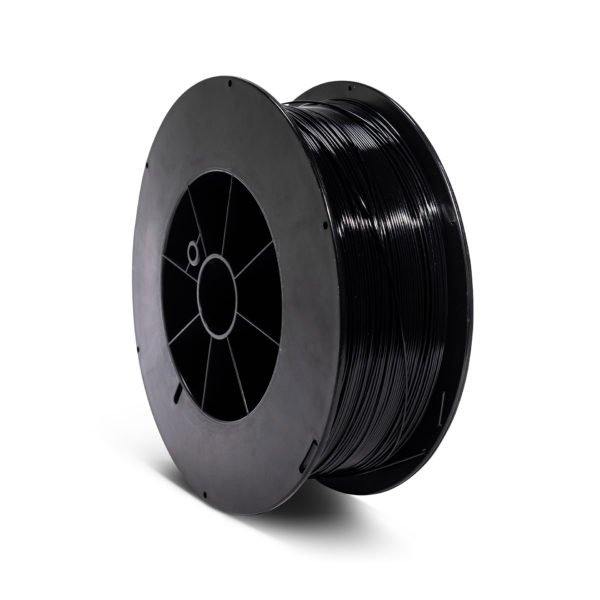

Available to pre-order, Essentium Altitude can be used on any open-source FDM 3D printing system, including Essentium's High Speed Extrusion (HSE) machines. It also complies with Essentium's certificate of conformance, which provides individual spool traceability through the ISO and AS9100 quality process.

Nirup Nagabandi, Ph.D., Vice President of Materials Engineering, Essentium commented: "We are excited to introduce Essentium Altitude, our latest innovative material that drastically expands the usability of 3D printing for outdoor and high-altitude applications. Engineered to withstand extreme cold, ultraviolet rays, and flames, Essentium Altitude sets a new standard for high-performance parts in industries such as aerospace, automotive, cold storage, maintenance, and construction. We will continue working with our partners and customers to drive a step-change in polymer advancement, enabling manufacturers to use AM for applications never imagined."

Essentium is exhibiting at the RAPID + TCT event in Chicago from booth #3818 between May 2-4.