If you or your children (and it’s okay if it was in fact you) were left distraught last week by the news that the Natural History Museum is set to make Dippy the dinosaur homeless, fear not, there may be a solution.

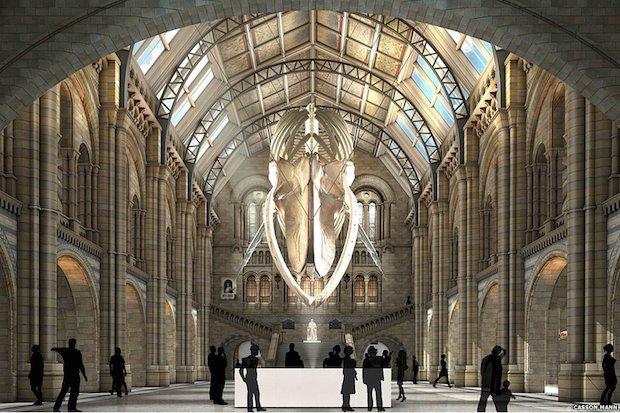

Residing in the museum for 109 years, everyone’s favourite diplodocus is set to be removed from the entrance hall of the London hotspot and replaced by a blue whale skeleton.

In response to the news, fans of Dippy have launched a #SaveDippy Twitter campaign to ensure the beloved model stays in its rightful place in the main Hintze Hall.

But the museum insists that it is time for a change, after all the model is not in fact made from genuine bone but composites which may need replacing after such a long lifespan. At the rate that 3D restoration is moving and creeping into the museum industry’s consciousness, 3D printing could provide a suitable solution to ensure the prehistoric creature lives on.

3D printing has played a huge role in digitising history for future generations. Scans of prehistoric bones have been collected and reproduced in cases like the 50ft Dryosaurus model by GoEngineer and projects such as the Smithsonian Digitization Program which has ambitious plans to scan every artefact in the Smithsonian Institutes collection and present them on a virtual platform.

Dippy is one of 10 replicas based on a near-complete skeleton of a real Diplodocus housed at the Carnegie Museum of Natural History in Pittsburgh. It is possible that the model could be 3D scanned and reproduced in new materials that would give Dippy a new lease of life. With current material options and research possibilities the dino could be rejuvenated and used as much more than just a centrepiece. On a larger scale, the original scan could provide other museums around the world with the opportunity to utilise the technology and have their very own Dippy in their halls.

The museum believes that the genuine blue whale skeleton, which already features in the museum grounds, will provide more value in both research and educating children on the responsibility humans have to other living things.

3D scanning could prove extremely valuable for both animals if digital versions of the creatures were made readily available for all to see. Scientists could use this data to further research and children could access the information in a virtual museum environment online. The Fitzwilliam Museum at the University of Cambridge recently set up a similar model offering a digital version of its collection which they then used to print and sell models from in its shop, opening up a brand new revenue stream. Or Dippy could make like NASA and become available as a downloadable model that children can print themselves at home (in miniature form, obviously, unless you’ve got a huge garden).

Dippy’s challenger to the throne could also benefit from 3D for scientific research. Speaking with the BBC, Richard Sabin, vertebrates collection manager at the Natural History Museum, suggested: “"Just the act of moving it will be great for science because we'll scan every bone, and that means any researcher will be able to study it and even print 3D parts if they want to."

For now it looks like the museum's plan is to send Dippy on a UK tour when his residency at the museum comes to an end in 2017. Though it will be sad to no longer have Dippy’s face greeting visitors to the museum, it is a welcome opportunity for the rest of the country to get a chance to see him. However, if the museum does decide to give Dippy the 3D treatment, perhaps that opportunity could extend to the whole world.