NASA, the United States federal government’s space exploration division, has revealed it is using Made In Space’s Additive Manufacturing Facility 3D print radiation shields.

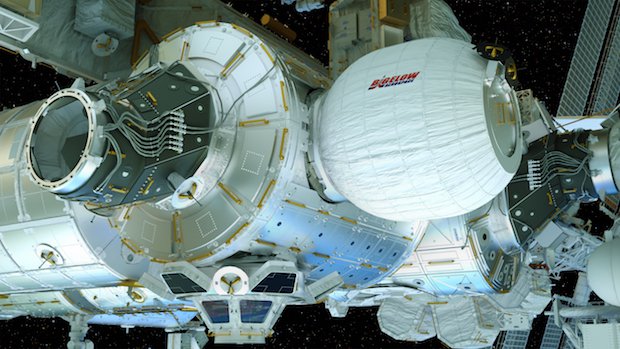

The radiation shields are being used to cover one of two Radiation Environment Monitors inside NASA’s Bigelow Expandable Activity Module (BEAM). Launched last year, BEAM is an expandable habitat technology demonstration attached to the International Space Station (ISS).

This week, NASA published an update as the BEAM reached the halfway point of its planned two-year demo. Within this article was the revelation that crew aboard the ISS has printed a radiation a shield, with thicker shields to follow later this year. The thicker shields will determine whether the safeguards work effectively to block radiation. The first shield implemented was printed back in April 2017 at 1.1mm thick. Over the next few months, this shield will be replaced by two more thicker shields, each thicker than the last, measuring around 3.3mm, and then 10mm.

Made In Space’s Additive Manufacturing Facility was launched in March 2016 and has since been a permanent fixture aboard the ISS. As per their agreement, Made In Space have ownership of the 3D printing platform, while NASA, among other commercial customers, use it as a service. Over the last 15 months, the Additive Manufacturing Facility has been leveraged to produce an array of parts, tools, devices and multi-part assemblies for use on the ISS. The radiation shields are the latest in a growing list of applications.

BEAM was developed to decrease the amount of transport volume for future space missions. Requiring minimal payload volume on a rocket, the habitat expands after being deployed in space, potentially, and hopefully, providing a comfortable area for astronauts to live and work. Additionally, BEAM provides a degree of protection from solar and cosmic radiation, space debris and other elements of the space environment.

This week’s BEAM update highlighted that the expandable module is showing that soft materials can perform just as well as rigid materials for habitation volumes in space. Researchers back on earth, at NASA’s Langley Research Center in Hampton, Virginia, have been analysing data from internal sensors, designed to monitor and locate external impacts of orbital debris. So far, they have recorded a few probable micrometeoroid debris impacts, as expected. However, BEAM has also performed as expected, preventing debris penetration with multiple outer protective layers.