Leading provider in additive manufacturing and large-scale EB welding systems Sciaky has entered a partnership with small-scale high-volume EB welding systems provider EVOBEAM.

The US-headquartered company - which is a subsidiary of Phillips Service Industries - specialises in large vacuum chamber EB welding systems with top-of-the-range internal moving guns. These systems utilise low voltage and high power and are well suited for large-scale parts.

Germany-based EVOBEAM specialises in high-throughput, small vacuum chamber EB welding systems with external guns. These systems use low voltage and low power and are ideal for the rapid production of small-scale parts.

Under terms of the agreement, Sciaky and EVOBEAM will co-market and co-sell each other's EB welding technology, providing a wide range of EB welding solutions for an international customer base.

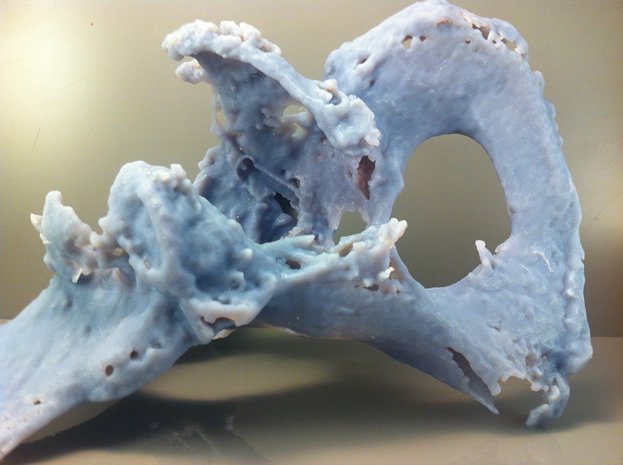

The deal includes Sciaky's innovative additive manufacturing process known as Electron Beam Direct Manufacturing, which remains the only large-scale, fully-programmable means of achieving near-net shape parts.

General Manager of Sciaky Mike Riesen commented: "Sciaky is very excited about the partnership with EVOBEAM.

"By combining forces, Sciaky and EVOBEAM offer a wide range of proven, cost-effective EB welding and EB Additive Manufacturing solutions that can't be found anywhere else."