At SOLIDWORKS World 2017, which is taking place in Los Angeles this week, Stratasys has announced a partnership with Dassault Systèmes to provide next generation design tools that improve the functionality, efficiency and weight ratio of additively manufactured production parts.

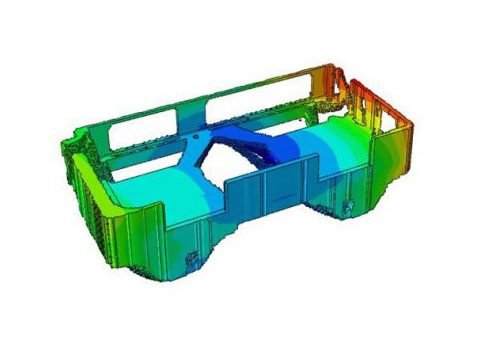

The collaboration with Dassault Systèmes’ SIMULIA will enable final part designs that are optimised for weight and strength for aerospace and automotive applications. Capabilities include design optimisation for light parts, strength and fatigue analysis for load bearing parts, and print process simulation to provide further insights into the residual stresses and performance.

“For additive manufacturing to reach its true potential, engineers need tools that will allow them to harness the virtually limitless geometric freedom that it provides. By fully simulating the unique characteristics of the FDM process, we’re able to bring unprecedented accuracy and speed to the design and validation process,” Scott Berkey, CEO, SIMULIA, Dassault Systèmes, explained. “We’re pleased to be partnering with Stratasys to bring these critical capabilities to customers.”

“Stratasys shares Dassault Systèmes’ vision for a fully integrated, end-to-end design to additive

manufacturing solution. This partnership brings Stratasys one step closer to that vision with high performance simulation tools that accurately represent the Fused Deposition Modelling process,” Jon Stevenson, Senior VP Global Software, Stratasys added. “We believe the solution’s predictive capabilities and efficient workflow will significantly expand the range of parts that can be confidently produced with Stratasys FDM-based 3D printing solutions. These are already being used to create production parts by companies like United Launch Alliance, Opel, Volvo Trucks and Daihatsu.”

Furthering its partnership with Dassault, Stratasys also announced this week a GrabCAD Print Add-In for SOLIDWORKS to allow users to estimate and print parts for a range of Stratasys machines, including its new F123 Series, without leaving the SOLIDWORKS environment.

Visitors to SOLIDWORKS World 2017 will be able to learn more about these capabilities in Stratasys’ booth #701 in the Partner Pavilion.