Large industrial 3D printer manufacturer, Titan Robotics featured its latest technology, The Cronus, at the CES 3D Printing Marketplace sponsored by TCT last week.

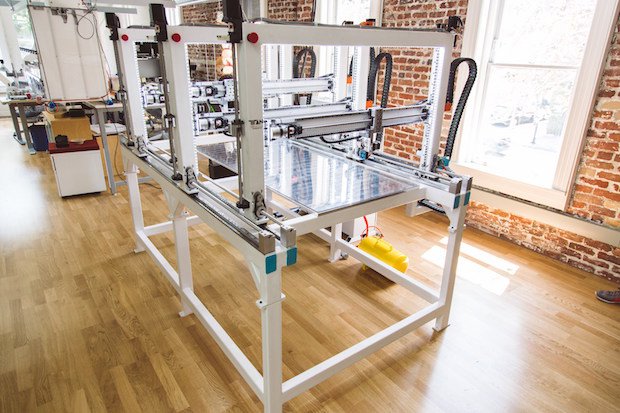

The multi-gantry FFF style 3D printer encompasses five print heads to allow bigger builds to be produced in a shorter time scale. These five print heads operate on five separate moving bridges using Titan’s unique offset gantry design.

Built using the Project Escher technology from Autodesk, The Cronus uses Netfabb software. Titan claim to have launched a ground-breaking solution for higher-speed, higher-detail industrial scale parts, combining Autodesk’s Project Escher and Netfabb innovations.

“It’s really exciting because (The Cronus) solves that problem of time when it comes to large format 3D printing,” said Maddie Garrett, Customer Relations at Titan Robotics. “You have five print heads at once so you can print something very big and complex in a fraction of the time it would take on a single head 3D printer. Autodesk does have a Cronus at their facility in San Francisco so it’s a really exciting technology and we’re really proud to be on Netfabb with them.”

The build volume of the machine is 77 x 30 x 20 inches. It has five overhead gantries, each with a Bulldog Extruder and an offset design. During the production of The Cronus, Titan used an all-welded steel frame which was CNC-Machined, as well as ball screws and profile linear rails on the entire machine ensuring its industrial-standard quality. Additionally, the machine has closed-loop Servo motors to guarantee high position, high speed and high accuracy.

Titan’s new technology is available as an open-air machine for printing in PLA and PETG materials, or with a heated enclosure to allow for printing with high temperature plastics, such as ABS, PC+PBT, HIPS and others. The Cronus, which will be available for purchase from next month at an as yet unspecified price, is designed and built with quality electronics and precision components on all axes to offer maximum speed, accuracy and reliability, according to the Titan website.

The Cronus technology was officially introduced at CES, and was exhibited on the show floor all week.