ALOFT AeroArchitects and Spectrum Networks, LLC are manufacturing certified, flight-ready components for 'some of the world's most exclusive aircraft' with Markforged composite 3D printing technology.

The parts are being installed on aircraft serving heads of state, governments and 'ultra-high-net-worth' individuals, according to ALFOT and Spectrum.

Markforged's FX10 platform is being utilised to design and manufacture replacement lighting and interior parts, with turnaround times being measured in weeks rather than months.

In 2024, Spectrum Networks produced over 10,000 certified flight parts using Markforged printers, with some helping to modernise aircraft interiors, others reducing downtime, and all helping to maintain the operational readiness of the fleets.

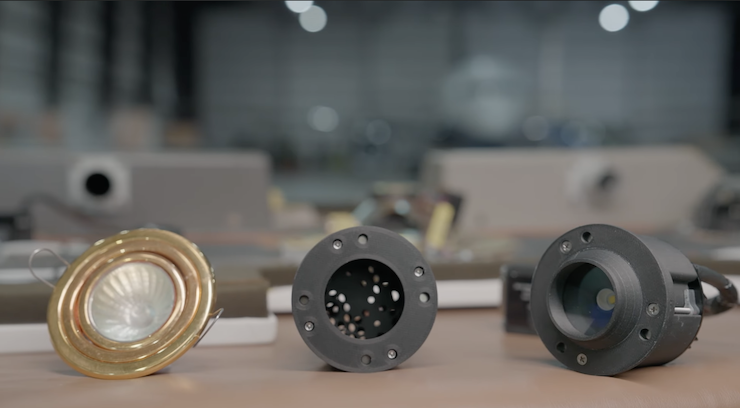

One such application is Spectrum Networks’ SPN 31 LED retrofit. Originally developed to replace outdated halogen fixtures on 20-year-old aircraft panels, the component was engineered using Markforged’s Continuous Fiber Reinforcement (CFR) technology to achieve superior structural integrity and a surface finish suitable for direct installation. Once additively manufactured, each part undergoes automated laser micrometer inspection when printed on the FX10, generating a layer-by-layer conformance report — an innovation that has accelerated regulatory acceptance within the FAA and global aviation authorities and shows added value for additively manufactured parts for aerospace and aviation.

“Our customers expect absolute reliability. These aren’t just private jets; they’re aircraft transporting world leaders and governments,” said Colby Hall, Director of Technology at ALOFT AeroArchitects. “Markforged’s technology allows us to receive parts with unmatched precision and traceability while cutting lead times from up to six months to just a few weeks.”

“You’re able to pull the part right off the machine and ship it out the door, as is. With Continuous Fiber Reinforcement, we noticed quickly that it gives us structural properties that we never thought were possible,” added Niel Gunnarson, President and COO of Spectrum Networks, LLC. “Our customers are able to use that information and propose designs that they need using those benefits.”

“ALOFT and Spectrum’s work demonstrates the power of Markforged to meet the highest levels of safety, quality, and performance demanded by the aerospace sector,” offered Dave Stehlin, CEO at Nano Dimension, the parent company of Markforged. “This collaboration shows how our technology is enabling customers to eliminate supply chain delays and deliver certified parts on demand — even for the most demanding missions. Our connected additive solutions enable aerospace manufacturers to move faster, eliminate obsolescence, and modernize complex supply chains.”