Rail transport systems manufacturer Alstom is using Wire Arc Additive Manufacturing (WAAM) to produce vehicle components ‘at short notice.’

The company is leveraging WAAM technology from GEFERTEC, having worked with the German machine supplier since 2020.

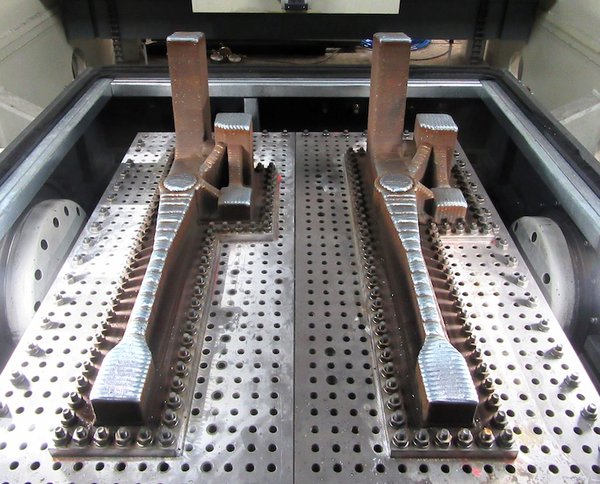

Five years ago, GEFERTEC produced the first wheelset bearing cover for Alstom using WAAM technology, with Alstom returning to use the company’s additive manufacturing services recently to produce a yaw damper for an older rail vehicle. Originally a cast steel component, the yaw damper is located between the bogie and car body, helping to ensure vehicle stability at high speeds and on curvy routes. Reproducing this part using steel casting would have taken too long and been too costly, so Alstom turned to GEFERTEC.

Initially, GEFERTEC’s team carried out a feasibility study based on the material and geometry data, before selecting the material, defining the tool paths and establishing the production parameters. Existing design data had to be converted into a format suitable for the additive process, with machining allowances also having to be digitally integrated, but GEFERTEC was able to manufacture the part in a timely manner.

Since the dampers are exposed to extreme loads and must adhere to stringent regulations, an extensive testing process – inclusive of static and dynamic testing – ensued. Within 100 days of the feasibility study commencing, however, the additively manufactured part was delivered to Alstom.

“The transparency during project execution and in the evaluation of tests was convincing,” said Dr.-Ing. Uwe Jurdeczka, Head of the Innovative Production Technologies Group at Alstom. “Sharing all results turned out to be uncomplicated. In the future, it makes sense to design components for additive manufacturing right from the start, especially in view of rail sector trends like lightweight construction and functional integration.”