Address:

Unit 4, 136 Mooringe Ave, South Australia 5037, Australia

Phone:

+61 429 550 593

Email:

info@aml3d.com

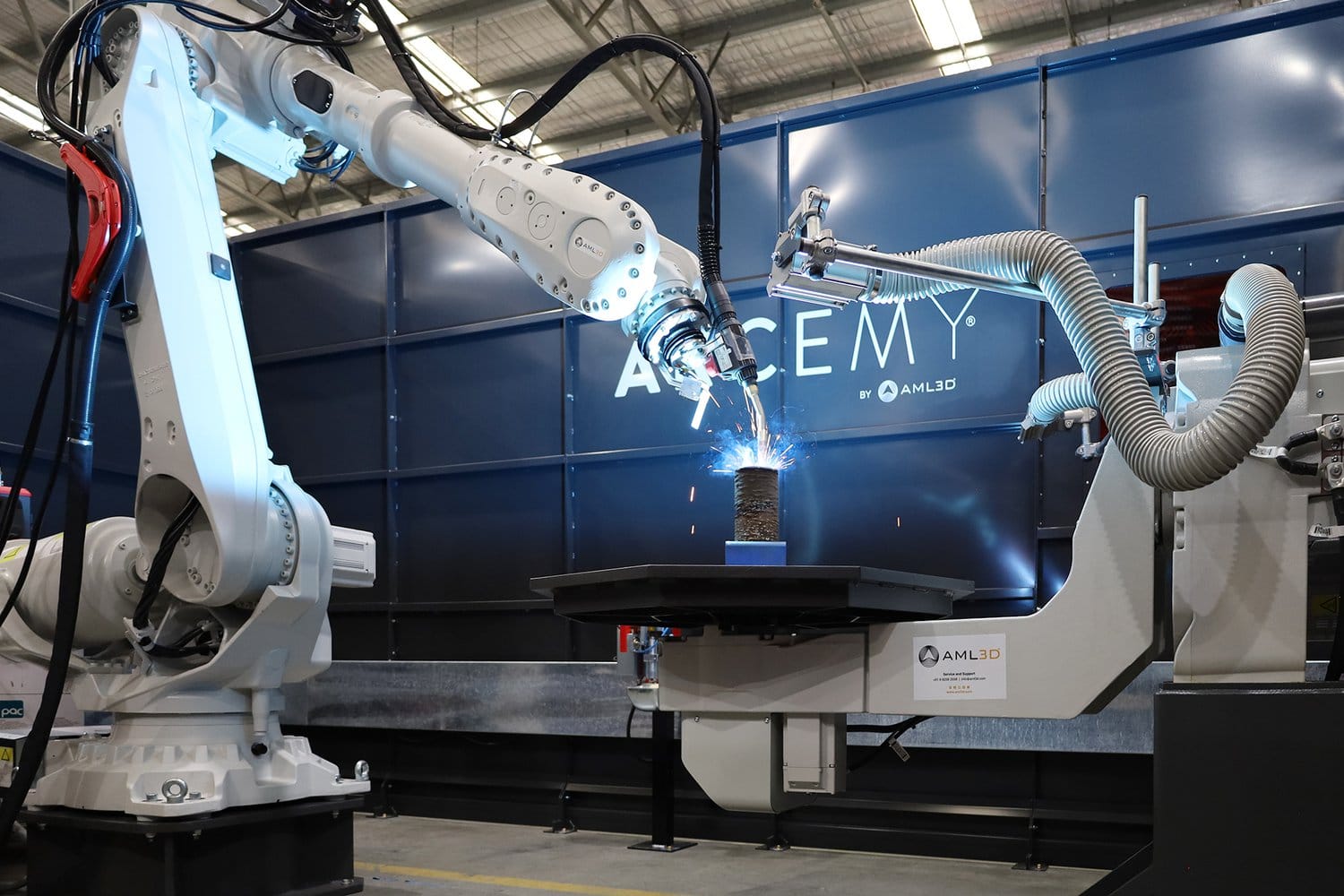

AML3D is a pioneering manufacturer of industrial‑scale metal additive‑manufacturing equipment. The company develops Wire Additive Manufacturing (WAM®) technology and builds the ARCEMY® family of metal‑printing systems. By combining advanced robotics, proprietary software (WAMSoft® and AMLSoft™) and a patented wire‑feed process, AML3D produces large, complex metal components more quickly, with higher strength and at lower environmental impact than traditional manufacturing. ARCEMY® systems scale from small units (for parts up to 750 kg) through custom systems that can build components measuring tens of cubic metres. These machines use certified wire feedstock in aluminium, titanium, copper, nickel and stainless steels, and the software provides real‑time monitoring, process optimisation and predictive analytics to ensure high quality. AML3D serves a diverse set of industries—including defence, aerospace, maritime, oil and gas and general manufacturing—and emphasises sustainability, claiming material‑waste reductions of up to 90 per cent and energy savings compared with conventional methods