Bambu Lab has announced the launch of its latest desktop 3D printer, the H2C, promising ‘a new benchmark’ in multi-material printing.

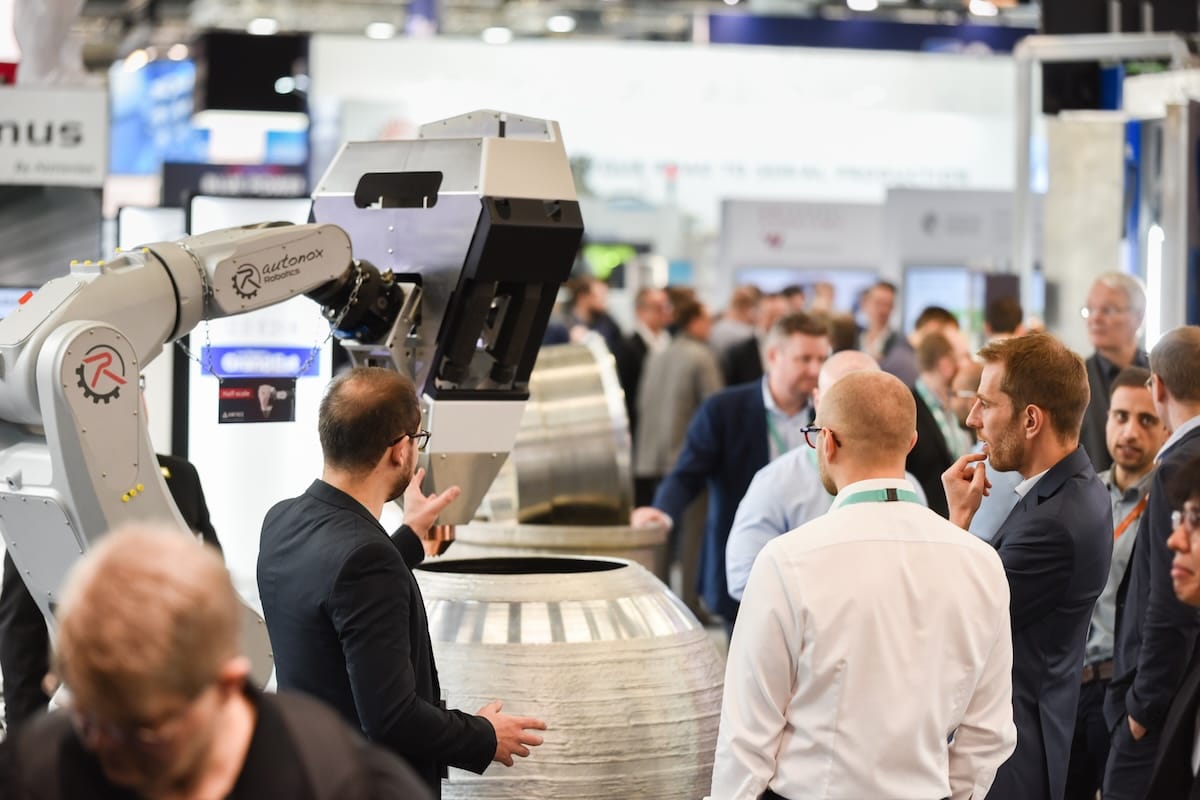

After teasing the machine this past summer, the company will be giving visitors to Formnext a first look at its new hardware, which has been built around a new wireless hotend swapping system.

The Vortek Hotend Change System supports six interchangeable contactless hotends to enable simultaneous printing with up to 24 filaments when used with its Automatic Material System (AMS). The hotend system is said to combat the issue of purge waste, and can eliminate the purge cleaning cycle entirely when printing with fewer than seven filaments.

Vortek has been designed to automatically recognise which hotend was previously used with which material and assign filaments to the appropriate one to reduce manual intervention and errors. Tool changes are said to take just seconds.

In addition to hotend enhancements, other features include a scanning process, which assesses the build plate, verifies nozzle compatibility with slicer settings, and analyses potential issues, while extrusion is monitored extrusion in real time. The H2C also features an inductive heating system which can reach working temperature in just 8 seconds, plus temperature and material flow control, supported by a PMSM servo extruder, which generates extrusion forces up to 10 kg for efficient flow control and stability at high printing speeds.

There are six versions of the H2C being offered. Prices starts at 2,249 EUR for the H2C AMS Combo and go up to 3,849 EUR for the H2C Laser Full Combo (40W laser) + Ultimate Set. Sales availability across EU, UK, CA, AU and CN begins today while a release date for the USA is yet to be confirmed.