The BMW Group is using polymer filament and granulate from waste 3D printing powder and used parts to produce new additively manufactured components.

At the automotive giant, waste powder is generated from the production of thousands of components each year, and while previously being disposed of, is now being processed into new feedstock.

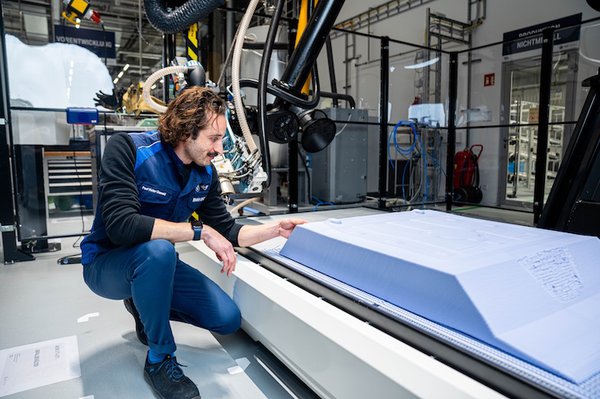

The recycled filament is being used at BMW's Additive Manufacturing Campus in Oberschleißheim, as well as various sites across the BMW global production network, to manufacture parts like auxiliary production devices and tools with Fused Filament Fabrication processes. Recycled granulate for Fused Granulate Fabrication technology is used to produce larger tools.

BMW's '3D printing loop' has its roots in its 'bottleUP' project, which commenced in 2018 to obtain 3D printing material from recycled PET bottles. Within a year, BMW was using recycled filament on a 'pilot basis' and by 2021, the first holders and auxiliary production devices were successfully printed using the company's own recycled filament. Each year, up to 12 tonnes of waste powder can be recycled into filament and granulate and can then be reused for the manufacture of auxiliary production devices in the plants and for pre-development projects at the Additive Manufacturing Campus. BMW says the use of these components reduces costs, enhances process efficiency and product quality, and improves ergonomics for employees at the plants.

Since establishing the process at the Additive Manufacturing Campus, BMW has begun rolling out its in-house developed recycling filament to other production facilities. Sharing its expertise, suitable 3D printers are tested and their print parameters optimised, with BMW also offering relevant skills development and training opportunities, inclusive of design for additive manufacturing and application-focused sessions on integrating 3D printing into the production environment. The next 3D printing facility to benefit from this offering is currently under construction at Plant Debrecen in Hungary and will support the new production plant for BMW's Neue Klasse concept going forward.

“I’ve been involved with this project from the very beginning and I’m thrilled to see how far we’ve come – from our initial ideas and attempts at startup level to now being able to produce large quantities of highly robust components from recycled filament at any BMW Group production location. It’s incredibly exciting to continuously develop and test new processes. The use of waste powder and discarded 3D printing components is a key element of a functional and efficient circular economy,” said Paul Victor Osswald, Project Manager for Predevelopment Non-Metals.

BMW has long been a user of 3D printing technology, with every BMW Group plant now equipped with an additive manufacturing system. With this capacity, several hundred thousand components are manufactured every year, from ergonomic and occupational safety solutions for employees to scratch protection, fitting aids and special manufacturing equipment, as well as gauges, templates, special tools and tool organisation.

Building on this 3D printing expertise with its closed loop workflow for polymer 3D printing materials, the company says a 'wide variety of components' are now being printed with recycled filament. One example is 3D printed support pedestals used in applying decor to the trim panel of motorcycles at BMW's Motorrad plant in Berlin. These parts are customised to fit the trim panel components precisely and also feature locking mechanisms to ensure parts are held securely in place. At BMW Group Plant Dingolfing, engineers have developed their own fitting aids with recycled filament to prevent screws from being lost during their assembly in the vehicles. Using 3D printing, a holder for magnetic screw attachment on various cordless screwdrivers has been developed which enables the screws to be carried safely.

Read more:

BMW goes bionic: A closer look at BMW's 3D printed robot grippers

BMW 3D printed more than 400,000 parts worldwide last year

The Ultimate Printing Machine - How BMW is applying 3D printing to commercial vehicles