Dyne Testing has published a white paper titled “The Importance of Measuring Organic Contamination Prior to Welding.” The paper goes on to discuss the impact of organic contamination, measuring methods, and how best to avoid contamination, as well as removal methods. Measuring and controlling organic contamination before welding helps to produce defect-free welds.

Organic contamination can lead to issues in weld quality, mechanical properties, and corrosion resistance. All these features are key in high-precision, high-integrity environments that users from the aerospace, automotive, medical devices, and electronics industries rely upon. Organic contamination can lead to serious defects like porosity and poor mechanical properties, like cracking. Testing methods can help users understand metal cleanliness while also enabling the tracking of the source of the contamination.

“Measuring and controlling organic contamination prior to welding is essential for producing defect-free, highest quality welds,” said Alison Fox, Dyne Sales Manager at Intertronics. “By employing simple but effective cleanliness testing, manufacturers can improve weld integrity, enhance product reliability, and extend the lifespan of welded structures.”

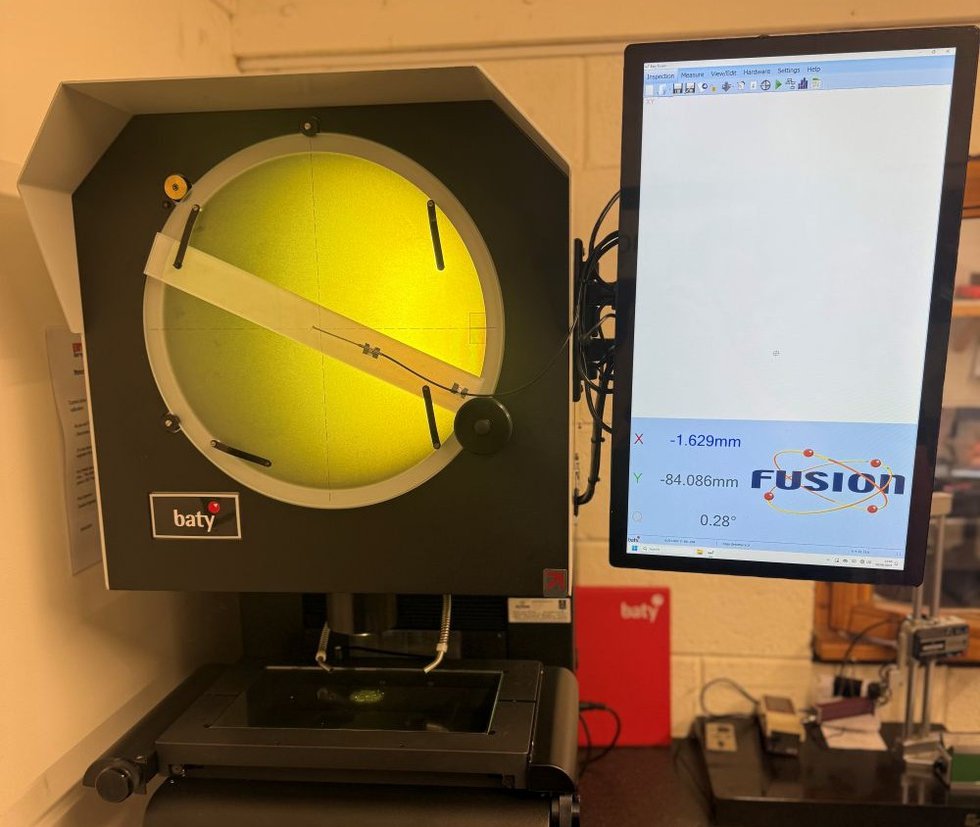

The company supplies tools for surface measurement and cleanliness, testing, and analysis. These tools include solvent wipe tests for residue transfer, contact angle measurement, and testing for relative fluorescence measurement (RFU) using its CleanoSpector device.