EuroMold used to mark the end of the year for TCT’s tradeshow calendar, after which the Christmas break stretched far into the distance like a field in Fargo. But not anymore. Now it signals a simple waypoint, a marker on the never-ending journey. Let’s not hold that against it though, as the 2013 edition of the event — the 20th in total — was a good one.

We arrived refreshed and revived with TCT Show + Personalize but a distant memory. Unusually for Frankfurt at this time of year the weather was generally fine, by which I mean dry and mostly above freezing. Christmas is an ever-present feature of late winter these days, and reminders from trees festooned with twinkling lights, to sprawling würst-infested markets abound across the city. The festive mood even carried to the show floor with a majority of the exhibitors upbeat and ready for the show to open.

As is often the case with larger shows, the first hour of each day sees the visitors start to trickle through the vast exhibition halls with a cacophony of chatter building slowly. Our interest has for the past few years been confined to Hall 11, with only the occasional excursion through to halls 8 and 9, and so it proved again for 2013. Hall 11 remains the busiest of the three halls (based on no data whatsoever beyond a keenly honed ‘show eye’ and idle gossip) as it houses the most innovative technologies in EuroMold’s mixed bag.

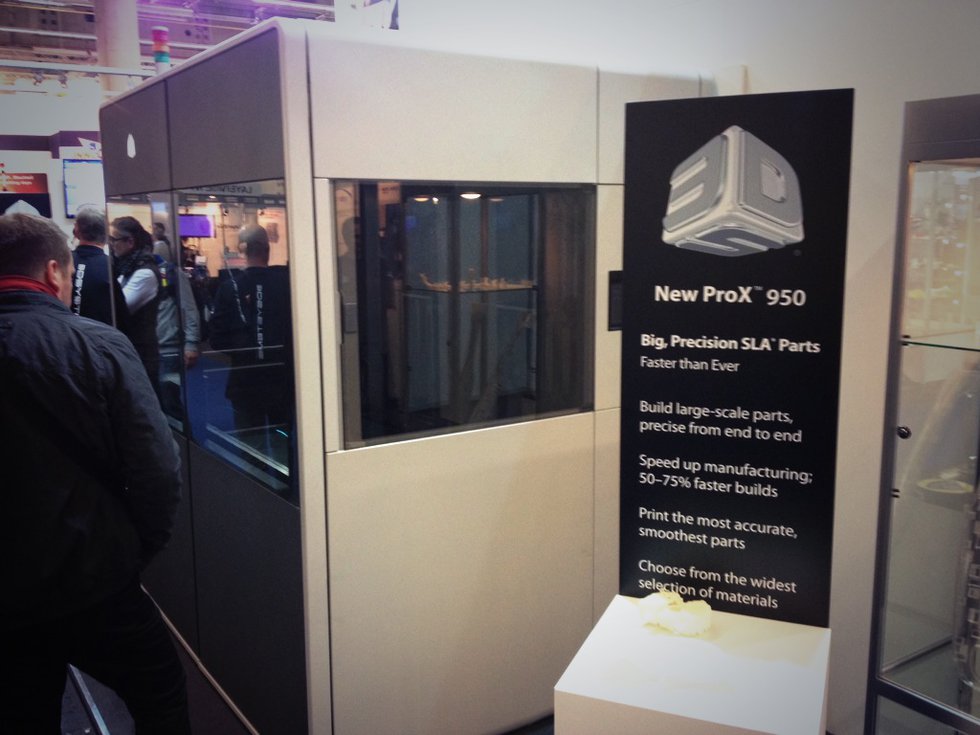

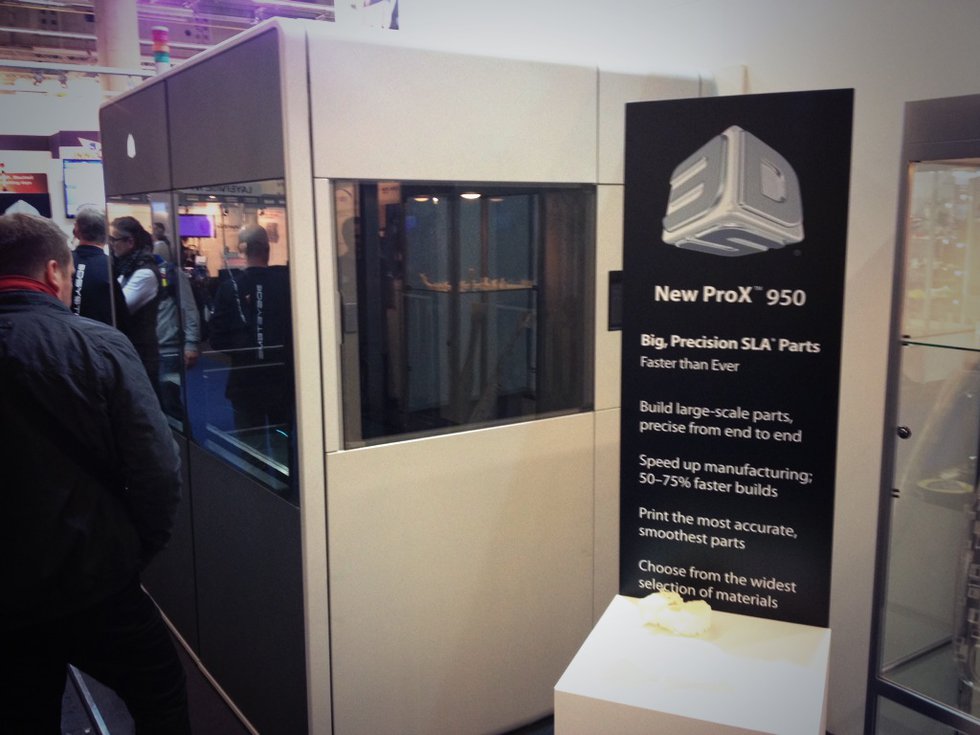

This is my fourth EuroMold (and I am reminded not to moan as our own Duncan Wood looks towards completing a 10-strecth in 2014) and in that time I have witnessed the change in not only the tech and business models but also the stands each company builds for the event. 3D Systems took a large, central space staffed by dozens (and dozens) of slickly branded staff alongside the new and updated machine range. Across the aisle Stratasys brought hall 11 the first double-decker stand, with a small but useful second floor for meetings and press events.

ExOne also invested in an expansive stand set up to house the large S-Print machine and subsequently large parts, as well as staff from the US and European offices. By contrast, Voxeljet’s stand was predominantly machine — the VX 2000 is enormous however. EnvisionTEC have also expanded to accommodate the new Xede line of printers which are significantly larger than the company's previous offerings.

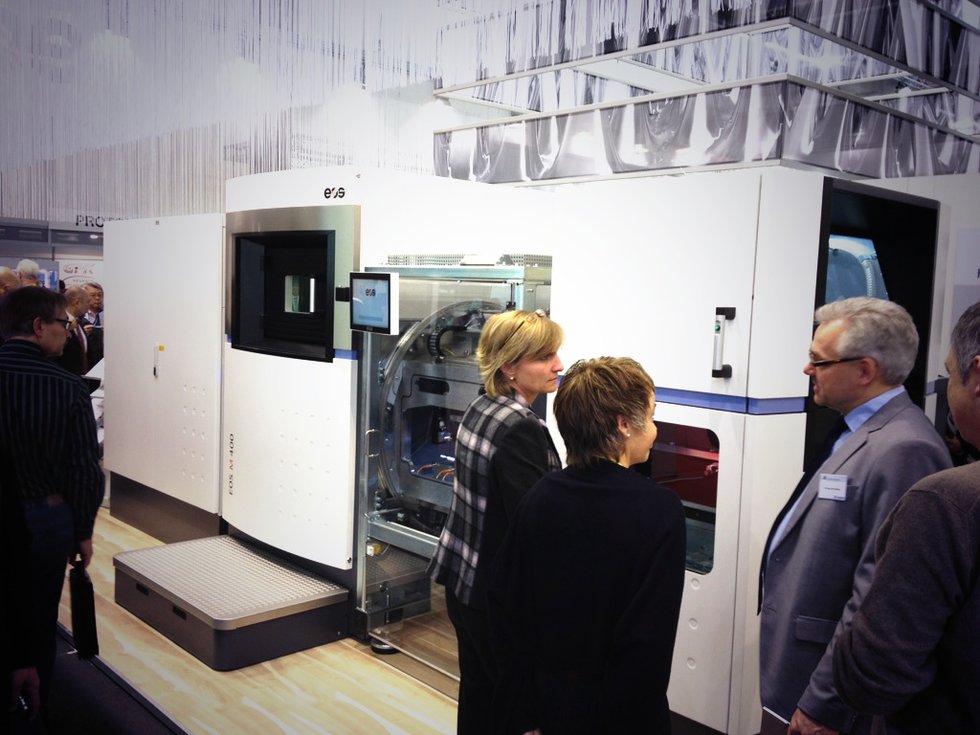

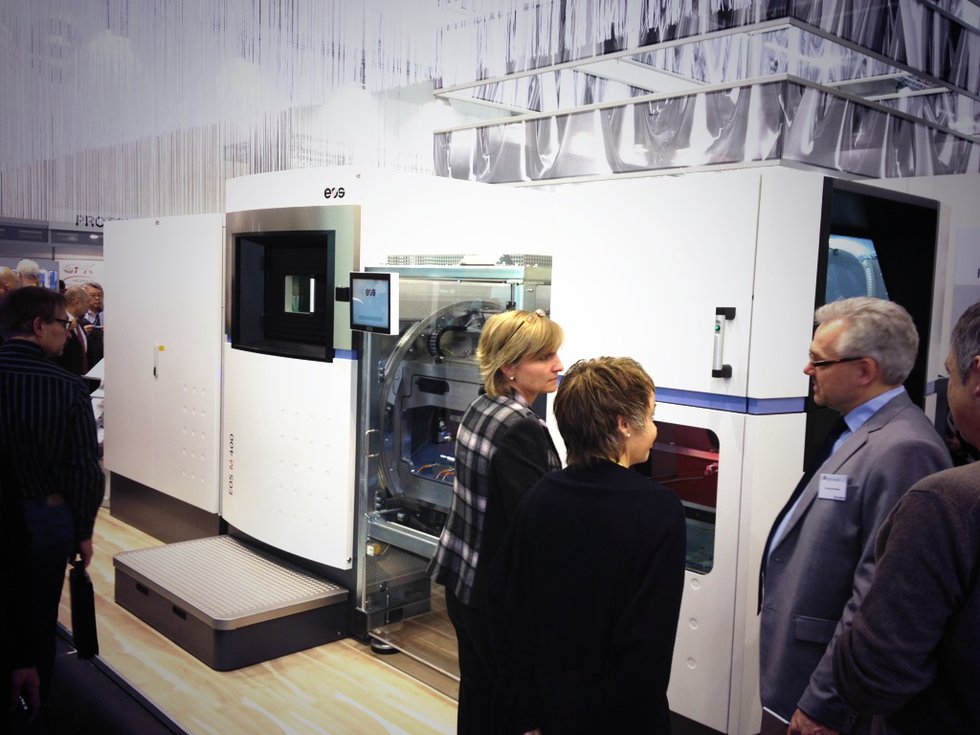

EOS managed to place the new M 400 machine onto its regular stand with ease despite the size (over 6m long), with room for a seating area and the usual smattering of parts from their polymer and metals machines.

Get your FREE print subscription to TCT Magazine.

Exhibit at the UK's definitive and most influential 3D printing and additive manufacturing event, TCT 3Sixty.

The most inventive stand for me had to be SLM Solutions beach-themed extravaganza. Complete with beach bar, loungers, seagulls, wave sounds, kites and the pièce de résistance — an enormous working lighthouse. Playing on their location close to Germany’s limited coastline, SLM also managed to work in the PSA 500 system, a machine that’s comparable in size to the EOS set up.

Newcomers Prodways were removed somewhat from the hub of the hall because, as Raphael Gorgé, CEO explained, it booked the stand late and had to settle for the top of the hall. The pull of the new company and its intriguing tech was sufficient for its stand to be packed for the duration of the even however, with visitors queing three- and four-deep to get a glimpse at the large-scale DLP based production system.

The hardest working team in show business, Mcor, took a large open stand with room enough to show off its full-colour system, the extraordinary parts it creates, and shout about the doubling in production speed now available.

Arcam used the event to announce a new machine, the Q20, and pleasingly the first sale of the system to France-based Poly-Shape. The new machine continues the theme set by others, the move the production.

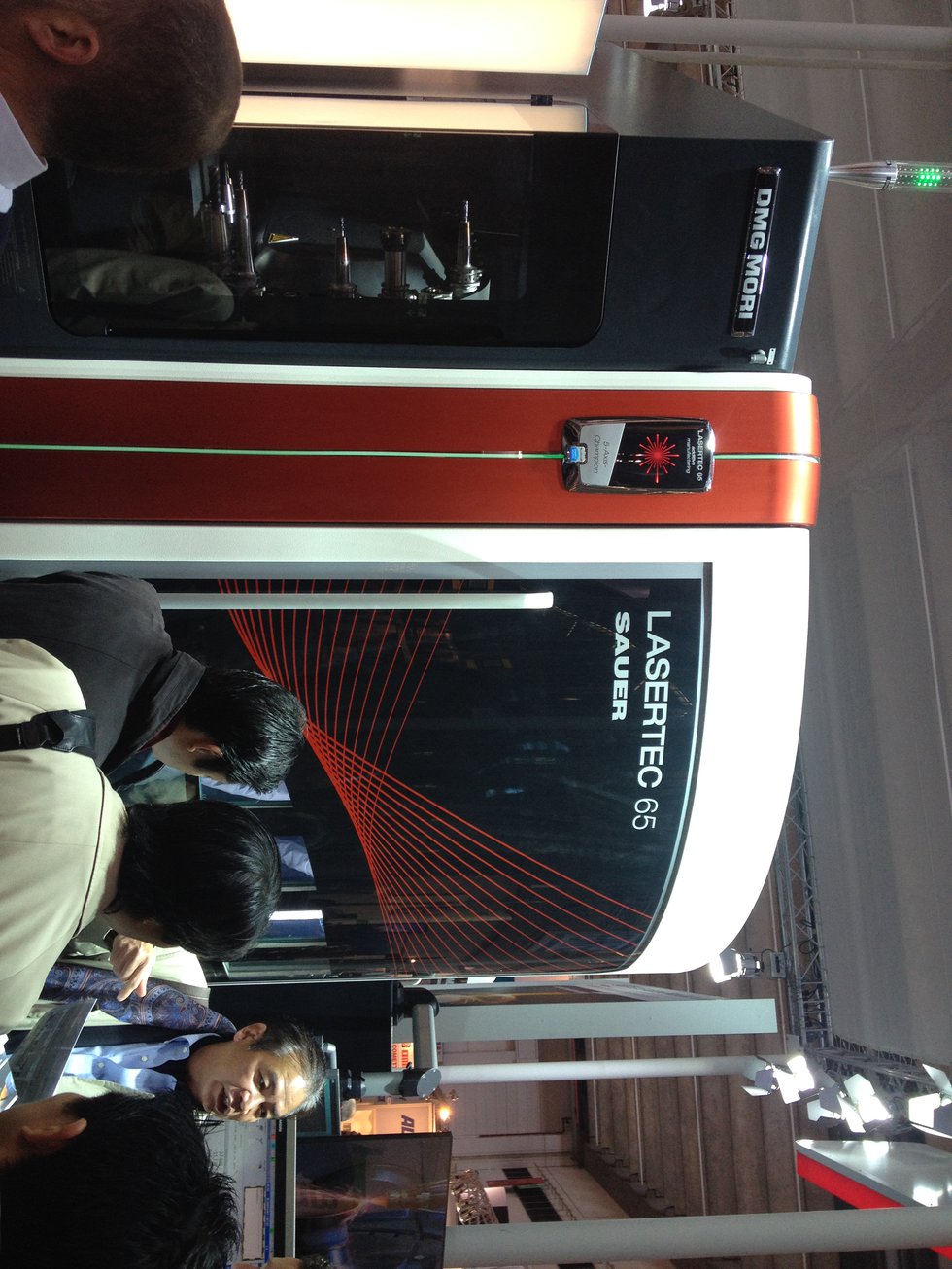

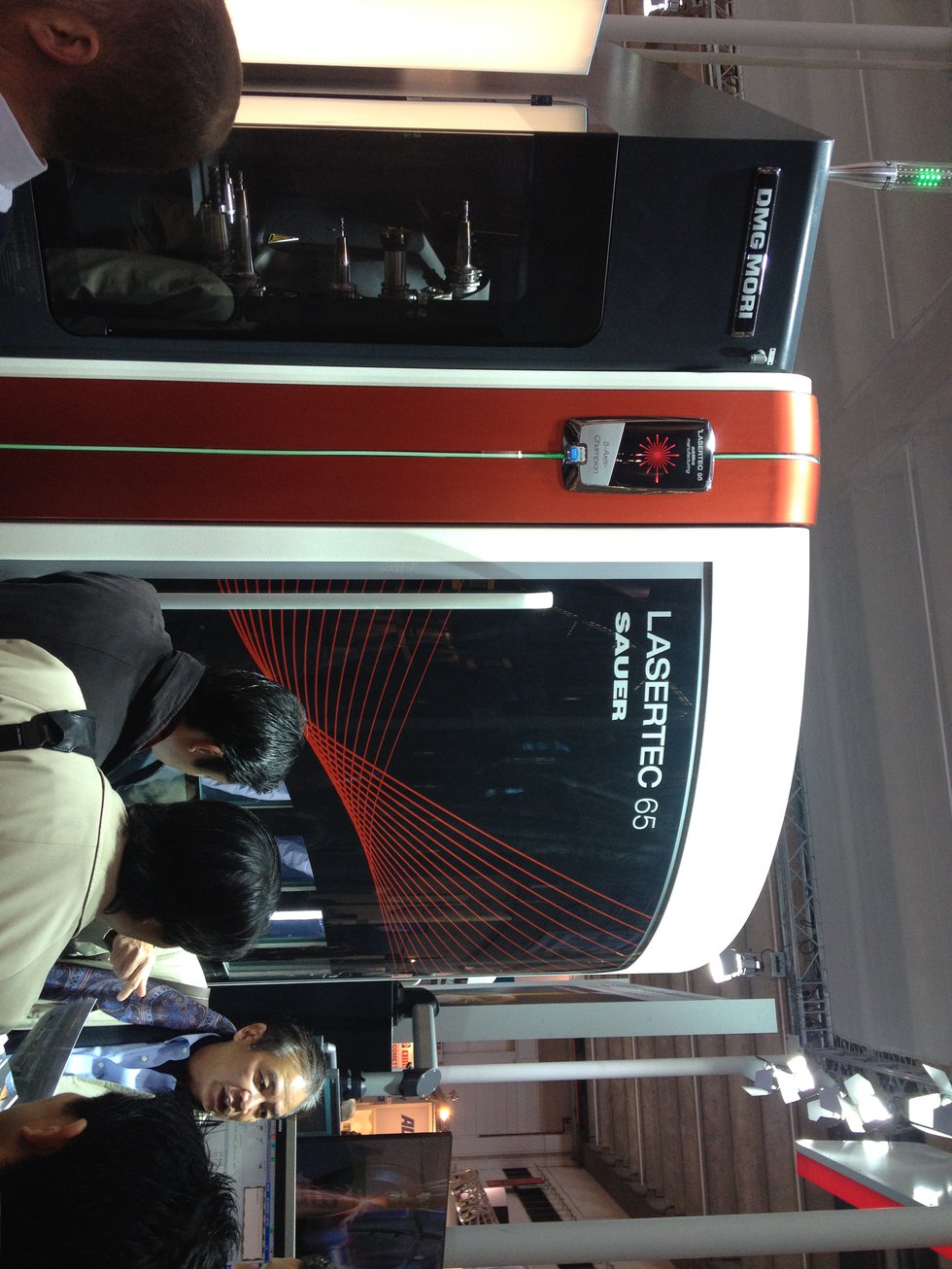

Over in hall 8, DMG Mori quietly showed off its hybrid additive + subtractive system, the Lasertec 65 Additive Manufacturing. Equipped with a 2kW diode laser deposition head couple with 5-axis machining capability. The machine is a partnership between Sauer Lasertec and DMG Mori USA and is aimed squarely at production of larger parts — the deposition rate of 3.5 kg/hr makes the system som 20 times faster than powder bed-based systems. Not commercially available until September 2014 (which ties in perfectly with TCT Show + Personalize by the way), the entrant of another ‘mainstream’ machine tool makers looks set to set the ruthless cat amongst the squabbling pigeons.

Mirroring DMG’s entrance into the metals sector was Arburg with its Freeformer, a remarkably similar concept of deposition head coupled to 5-axis workpiece holder (in the most advanced version). Perhaps a milling step could solve the perceived issue of surface finish?

There was plenty more happening on the show floor, all of which can be found in the @TheTCTMagazine and @prsnlz twitter streams, and across www.tctmagazine.com