FKuR Kunststoff GmbH, a company with a 20 year history in developing bioplastic compounds, has collaborated with Helian Polymers, a leading provider of 3D printing filaments, to develop a new blend of PLA material.

Reinforcing traditional PLA, which can sometimes be prone to brittleness and low impact strength, this new modified PLA has been optimised to provide improved processing and expand the applications for PLA in 3D printing.

Bioplastics such as PLA are particularly suitable for the FDM process due to their relatively low processing temperatures, which result in easier control of the printer. In comparison with commonly used ABS they can provide better printing accuracy and do not release hazardous vapours. However, this new form of PLA is a unique class of materials made using renewable sources and can produce biodegradable products.

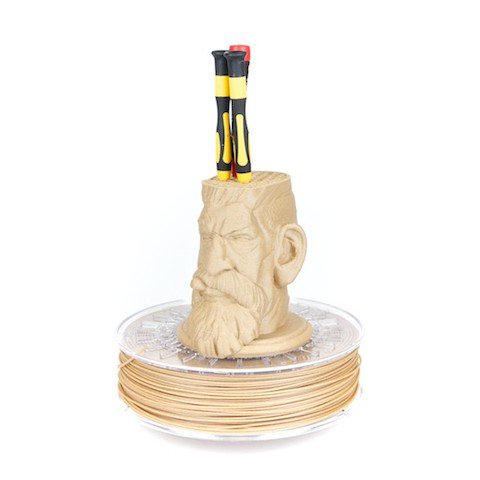

Colorfabb is set to supply the filaments which include ‘woodFill Fine’ and ‘BambooFill’ in a variety of colours. Both of these materials have been reinforced using wood fibre to give 3D printed products a natural wood aesthetic.

The materials will be shown at this year’s Composites Europe exhibition taking place between 7th-9th October at Fairground Dusseldorf.