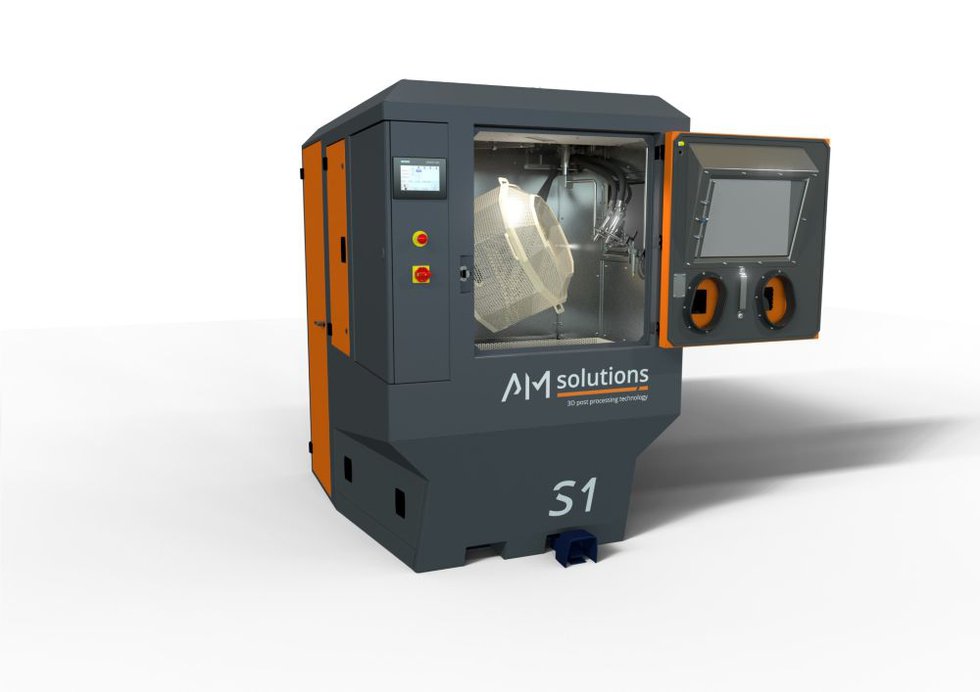

AM Solutions has announced that a fast-moving consumer goods (FMCG) company’s R&D facility has adopted its S1 automated post-processing system to boost its additive manufacturing (AM) capabilities. This highlights the company’s commitment to innovation and efficiency throughout the product development process.

The FMCG company will demonstrate the potential value that can be found at the early stages of the development cycle, where rapid prototyping is key in shaping future products. So far, the S1 system is making a significant difference in the day-to-day operation of the lab.

“We’re using additive manufacturing to create accurate, high-quality prototypes that support early-stage market research and help bring downstream teams (such as tooling) into the development process much earlier,” said a Spokesperson for the FMCG company. “But while the printing process was streamlined, post-processing was still a bottleneck. The S1 has completely changed that.”

Drawbacks of the old, manual process

Before this investment, the company relied on manual bead blasting using glass media. This process takes around four hours per day, requires significant operator involvement, and generates dust, which impacts the working environment. Additionally, this method can also influence the finish quality.

“It wasn’t just about the time spent each day (though saving 300 hours a year is no small thing), it was also about consistency, safety, and freeing up our team to focus on the more creative, high-value aspects of R&D,” the Spokesperson continues. “The S1 gives us a fully enclosed, automated process that handles both cleaning and surface finishing in one go, saving space and delivering repeatable results.”

How the S1 system aids the company

The 2-in-1 functionality of the S1 is key in the FMCG company’s supplier evaluation process. Competing systems need two separate machines, one for cleaning and the other for surface finishing. Needing two machines places a greater burden on space and workflow complexity. The compact footprint of the S1 is a clear advantage. Additionally, the 2-in-1 nature of the system ensures both processes can occur simultaneously.

“The other solutions we reviewed required more space and didn’t achieve the same finish quality,” said the Spokesperson. “The S1 has streamlined our entire process, and because it’s clean and enclosed, it’s improved the overall lab environment as well.”

The support provided by the AM Solutions team is another key benefit available to the FMCG company. Known for their finishing technologies expertise, the team can work closely with the adaptor to fine-tune process parameters and select the combination of media and compound to ensure consistency.

“What really set AM Solutions apart was their knowledge and willingness to engage with our specific needs,” concluded the Spokesperson. “They didn’t just sell us a machine; they helped us build a finishing solution that works for our parts, our materials, and our workflow. That kind of expertise is rare.”