It's that time of year again. As the additive manufacturing (AM) industry prepares for its annual trip to Frankfurt, we preview the 3D printing technologies and applications you can expect to see at this year's Formnext.

Taking place on November 19-22, as ever, the event promises a healthy amount of European debuts from additive OEMs alongside application and technology developments from across the AM ecosystem.

The TCT editorial team will be on the ground keeping you up to date on all of the latest news right here.

Addiguru showcases next-generation multi-modal in-situ monitoring | 11.0 B57

Addiguru will unveil its latest advancements in automated build analysis in Frankfurt.

Building on its success as co-winner of the ASTRO America Additive Manufacturing Challenge, Addiguru’s multi-modal platform introduces several key capabilities that help manufacturers detect and act on process issues 'far earlier than traditional systems allow.'

This includes automated analysis and alerts of recoat issues in real time, automated detection of process thermal anomalies, live investigations of process issues, and thermal history monitoring of individual parts.

GEFERTEC to display large-scale metal printing for industrial applications | 11.1 D31

At Formnext, GEFERTEC will showcase representative examples of completed component projects, including a 700 kg impeller for turbines, an emergency exit frame for aircraft, a toolprint for toolmaking, and a yaw damper console for the rail industry.

“The demand for large-format additively manufactured metal components continues to grow,” says Johannes Zuckschwerdt, Managing Director of GEFERTEC. “At Formnext, we’re demonstrating how WAAM is already ready for production today.”

The company will also showcase the new arcLab solution, which has been designed to meet the needs of universities and research institutions.

GEFERTEC is part of the Berlin Capital Region’s joint booth.

Lithoz presents a manifesto for industrial ceramic 3D printing | 11.1, C35

Lithoz will be showcasing a range of 46 additively manufactured ceramic casting cores on a single CeraFab S320 build platform. These highly precise cores demonstrate Lithoz’s advanced understanding of scaling up ceramic process control and microstructural integrity to ramp up serial production of casting cores for single crystal turbine blades. Ultra-precise Lithoz LCM printers as key technology enabled industrial production of highly complex casting cores meeting cooling requirements of future aircraft engines.

The company will also display an LCM-printed, 15-inch atomic layer deposition (ALD) ring, manufactured by Alumina Systems and designed by Plasway, for use in the semiconductor industry. Next generation LCM-printed cooling and heating plates and ceramic earmoulds for hearing aids will also be showcased to exhibit the capabilities of its ceramic 3D printing technologies.

M.TEC Engineering aims to make 3D printing predictable with new simulation method | 12.1, A123 & 12.1, B131

As it aims to transform 3D printing from an uncertain trial-and-error process into a fully plannable and simulation-supported process, M.TEC Engineering is introducing a simulation-based method that addresses dimensional accuracy, warping and layer connection validation.

Using advanced methodology and real material and process data, the solution is said to be able to reliably predict layer bond strength, distortion, and structural mechanics. It promises early fault detection, minimised prototyping cycles, reduced waste and the optimised use of materials.

"We only print what has been approved in advance," said Wolfgang Pelzer, Managing Director M.TEC ENGINEERING GmbH. "That's our credo."

M.TEC will occupy space on the stands of YIZUMI Germany (12.1, B131) and AKRO-PLASTIC (12.1, A123).

Incus to launch Hammer Pro25 metal 3D printer | 11.1, E59

Incus says the Hammer Pro25 has been designed to combine high precision, automation and throughput in one system, enabling users to move from prototyping to series production.

Among its key features is a capacity to print with 25µm lateral resolution thanks to dual scrolling projectors that enable simultaneous printing on two platforms. It can also achieve a material throughput of up to 980 cm3/hr with automated material refill and removal of finished parts, while allowing for layer thicknesses of between 10 and 100 µm. The build volume is 200 x 204.55 x 140 mm.

“With the Hammer Pro25, we are empowering manufacturers to scale up additive manufacturing with unprecedented reliability and efficiency,” said Dr. Gerald Mitteramskogler, CEO of Incus GmbH. “The system’s combination of precision and automation provides true industrial capability, while its surface finish drastically reduces the need for costly post-processing.”

Solukon to unveil new variant of post-processing system | 12.0, D71

Solukon is set to present a new variant of its SFM-AT800-S Special Version machine, which features automated part transport and depowdering combined with robotic finishing.

The solution have been developed in partnership with Grenzebach and Yaskawa.

Solukon believes the new system marks a significant step toward even greater efficiency and automation in depowdering and post-processing workflows.

Caracol introduces Eidos Manufacturing Software Suite updates | 12.1, C101

Caracol will present the new evolution of its Eidos Manufacturing Software Suite — the intelligent backbone of Caracol’s connected manufacturing ecosystem — at Formnext. The software update introduces next-generation features that integrate AI, as well as other manufacturing processes, and advanced sensing to enable more autonomous, adaptive, and high-performance production across its platforms.

The latest Eidos Manufacturing Software Suite features, developed for Caracol’s robotic platforms in collaboration with leading software and AI companies, featues the Eidos Builder and Eidos Nexus capabilities. Eidos Builer combines Caracol’s advanced slicing, simulation, and additive manufacturing capabilities with other processes such as scanning and milling in fully automated workflows, while Eidos Nexus is the 'control brain of the platforms' and boasts sensing, learning and smart control features.

Xenia to launch 15% carbon fibre reinforced material | 12.1, F98

Xenia will introduce a new carbon fibre-reinforced filament for extrusion-based 3D printing at Formnext.

The XECARB PA12-CF-ST is developed on a PA12 matrix and is said to deliver high strength, excellent abrasion resistance and low moisture absorption. It also boasts 15% carbon fibre reinforcement, which helps to achieve high mechanical performance, lightness and dimensional stability.

Xenia’s Super Tough Upgrade technology significantly enhances impact resistance and elongation at break, allowing the material to withstand shocks and mechanical stress.

Renishaw to introduce LIBERTAS software solution | 11.0, C11

Renishaw will launch the LIBERTAS software to address poor down-skin surface finish and the need for support structures.

The company believes these are two of the biggest challenges in metal additive manufacturing and is providing solutions through the dynamic adjustment of scan parameters across different sections of the built part.

At Formnext, Renishaw will host a series of software demos to allow engineers to understand how they can achieve smoother down-skin surfaces, complex geometries without the need for supports, and a reduction in waste and build time.

Stratasys to highlight series of applications alongside two new materials | 12.1, D121

Stratasys will showcase around 200 production-grade parts on its Formnext booth this year, demonstrating the capabilities of its five 3D printing technologies and 50+ material offerings.

Among the highlights are the new ToughONE WhiteS material for the J3 and J5 PolyJet 3D printers and the recently launched P3 Silicone 25A material. The former has been designed to combine flexibility and strength for demanding applications, while the latter has been developed to deliver true silicone parts with excellent tear resistance, elongation, and biocompatibility using the Digital Light Processing (DLP) printing platform.

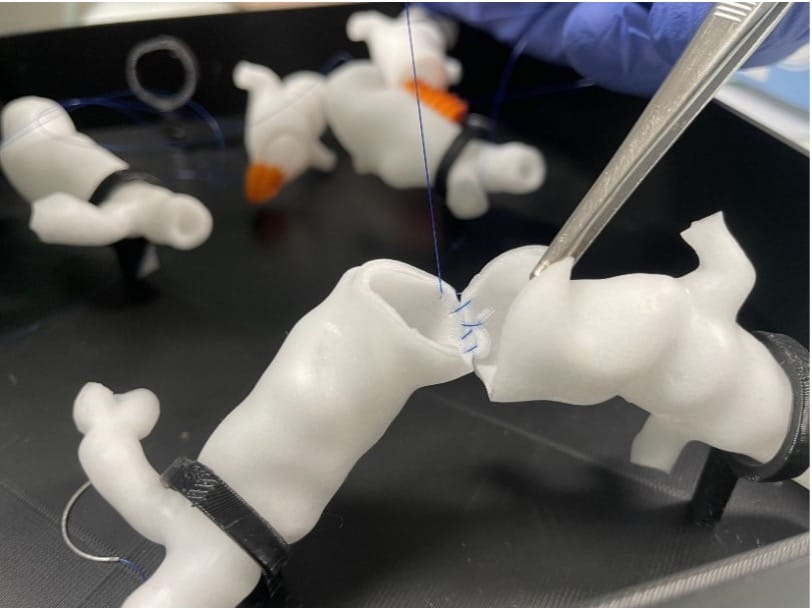

The company will also host a live surgical demonstration with Addion GmbH on its booth, with lifelike 3D printed models being used in an eyelid surgery demo.

Lynxter introduces new printing options for S300X LIQ21 | LIQ11 | 11.1, C69

Lynxter has developed two new modules to expand the S300X ecosystem.

The NEST – GEL option enables the production of ultrathin, smooth, and complex silicone parts, such as thin walls, lattice structures, and industrial bellows. The support material, in this case gel, is reusable and fully water-rinseable.

The NEST – POWDER option has been developed in partnership with 3Deus Dynamics and enables the production of soft silicone parts with complex designs, using reusable and water-soluble supports. This solution is suitable for medical applications like anatomical models, training models and simulators for medical device testing.

Arkema to showcase 'game-changing' powder bed fusion materials | 12.1, C129

Arkema will showcase its Orgasol PA12 powders, which have been engineered for high-performance 3D printing and are said to offer outstanding powder recyclability and superior surface quality.

This high-performance material for powder bed fusion technologies helps reduce material variable costs by up to 50%. On HP MJF technology, for instance, HP 3D HR PA12S, enabled by Arkema has been widely adopted by users across the globe.

Arkema has also established partnerships with Manifest Technologies, Axtra3D, and Carl ROTH, of which it will be able to share more details from its Formnext booth.

Nikon SLM Solutions announces integrations with AMiRIS and Oqton | 12.0, D119

Nikon SLM Solutions has announced two collaborations ahead of Formnext, first with Additive Assurance and now Oqton.

The metal additive manufacturing OEM said it will embed Additive Assurance’s AMiRIS technology inside its flagship NXG platform, which will use a near-infrared optical tomography system to simultaneously monitor all 12 of the system’s lasers. The integration is thought to be a first for the industry and promises a ‘significant leap forward for process monitoring’.

The second collaboration is the validation of Oqton’s 3DXpert build processor. It follows an several months of work which has resulted in a fully validated, production-grade workflow that enables users to prepare, manage, and execute AM build jobs with greater efficiency, consistency, and confidence.

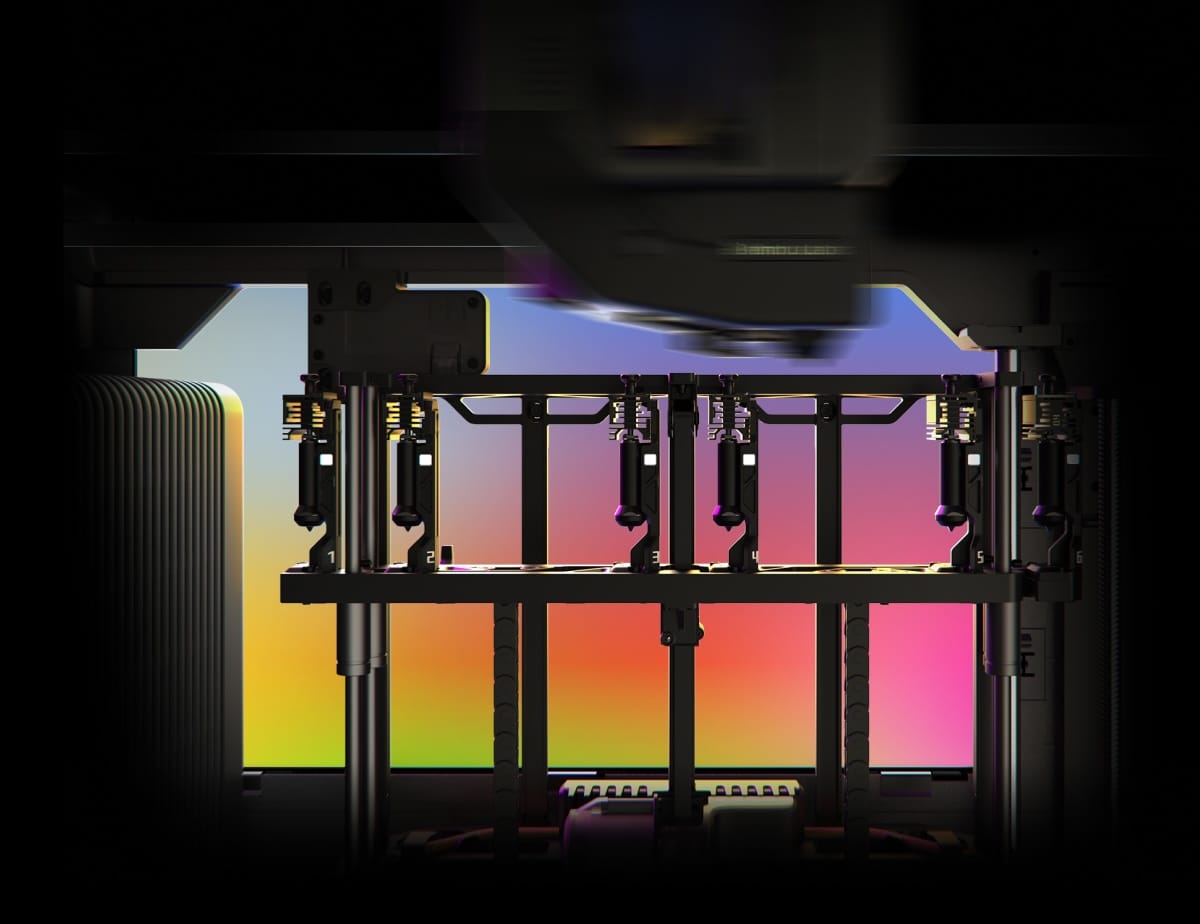

Bambu Lab to debut H2C 3D printer | 12.1, D11

After teasing this past summer, Bambu Lab will be giving visitors to Formnext a first look at its new H2C desktop printer.

The system features a wireless hotend swapping system named Vortek, which has been designed to deliver a cleaner solution to multi-colour 3D printing. According to a blog detailing this development, this approach is said to have reduced the hotend assembly down to just four parts - nozzle, heatbreak, thermistor, and a compact PCB - in a 20 × 15 × 56 mm form factor weighing 10g.

Bambu Lab said is expects to be ready to ship the H2C by the end of 2025 and will be providing demos on the show floor in Frankfurt.

DN Solutions combines subtractive and metal additive manufacturing | 12.0, C61

Korean machine tool manufacturer DN Solutions will present its latest machines to the European AM market at Formnext.

The company, formerly known as Doosan, is the third largest machine tool company and made its entry onto the industrial 3D printing sector earlier this year. At Formnext, it will present its latest DLX products alongside its 5-axis CNC DVF5000, underscoring its 'AM2CNC strategy', which combines additive and subtractive manufacturing.

DN Solutions will showcase its flagship DLX450D, designed for high-volume applications, and demonstrate how AM can be introduced into existing production processes to combine AM's design freedoms with the surface quality of CNC.

Rapid Fusion introduces containerised hybrid CNC & AM platform | 11.1, E35

Rapid Fusion will launch a deployable hybrid manufacturing system that can be set up in 25 minutes.

Following the launch of its 3-in-1 Medusa system earlier this year, Rapid Fusion has sought to release a hybrid CNC and 3D printing machine.

The company believes its new solution – Cerberus – will ‘change the way production parts are made in remote areas.’ Cerberus is a containerised machine ‘with every millimetre designed for rapid deployment, rugged operation and uncompromising performance.’ It boasts a build volume of 1200mm3, a pellet throughput of up to 17kg per hour, and 3kW of continuous spindle power. The machine offers bulk material compatibility, so any local polymers can be used, while operating up to 500°C for advanced composite production. It also benefits from dual independent heads to ensure zero downtime.

Altform to make its debut | 12.0, E139

Just in time for Formnext, Prima Additive by Sodick has unveiled its rebrand to AltForm. The new name follows the Japanese machining company's majority acquisition of Italian 3D printing OEM Prima Additive back in May, and is said to boost its position as a global contender in advanced laser manufacturing processes, including Laser Powder Bed Fusion (PBF) and Direct Energy Deposition (DED).

At Formnext, AltForm will debut its Print 300 and Print 400 Series LPBF platforms, built using a new architecture with modular build chambers, enhanced gas-flow stability, redesigned thermal management, and improved multi-laser coordination. These features are said to deliver industrial throughput, automation readiness, and tighter process control. The company will also premiere its unified software suite.