There are a huge number of 3D printers available for the at-home maker (maybe too many, as pointed out on Twitter today), most of which rely on extruding melted ABS and PLA plastics through a nozzle and building them up layer-by-layer.

The Veloso 3D printer that we have on the site already — HERE — has been doing the newsrounds for a while and will be familiar to some already. Using a process that looks a lot like Envisiontec's perfactory process (in as much as it builds 'upside down', uses photocurable resin and a digitally controlled light-source, DLP) the Veloso 3D printer seemingly creates some exceptionally high-detail prints.

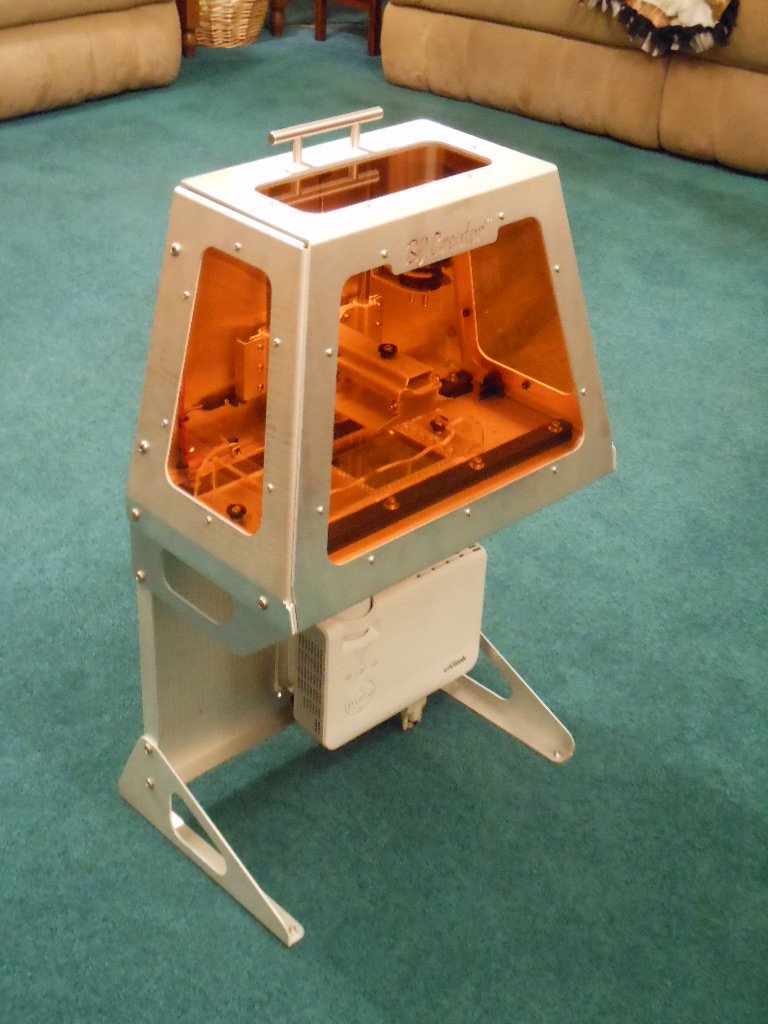

And now it has competition in the form of the amazingly professional looking B9Creator (not to say that the others aren't, of course). Using the same liquid resin and DLP set up, the B9C looks like an extra from a Star Wars scene and with that name I can see why.

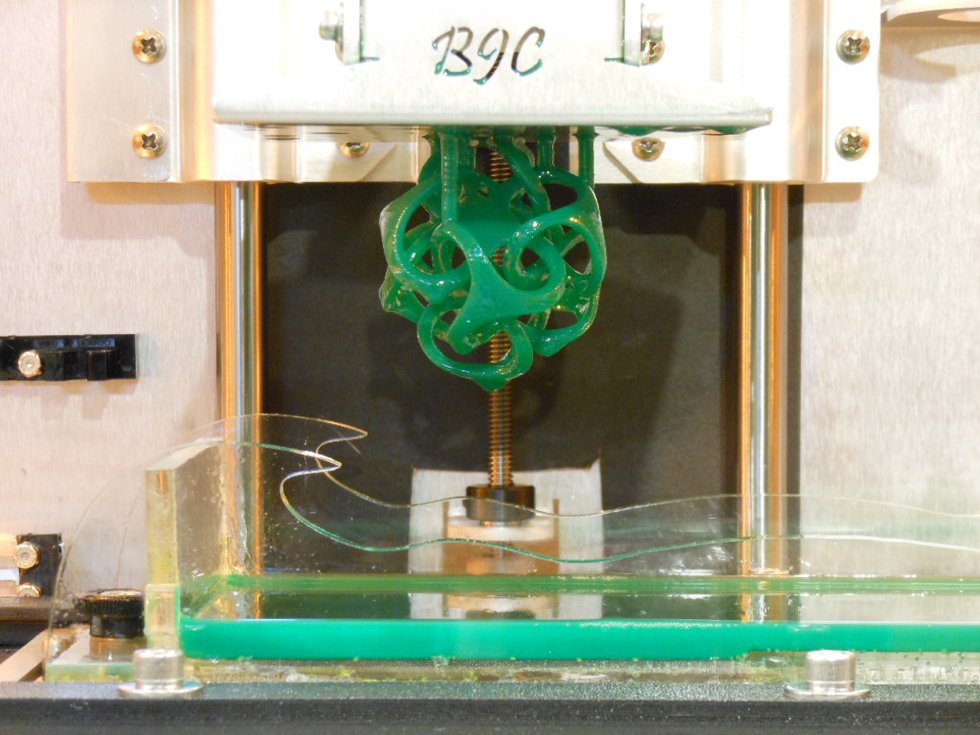

The B9C creates single coloured models (see images for a green and red example), and from the snaps on the printer's Kicktarter page there will be quite a few options in that respect.

The video in this article gives a walkthrough of the features of the B9C, including the control and safety mechanisms.

While the extrusion-based machines are cheaper, unless you are willing to spend maybe three times the cost of the B9C — on a Stratasys Mojo for example — you're unlikely to get anywhere near the resolution on offer here. Admittedly the additioin of liquid resin makes the day-to-day use a little more difficult with a DLP machine, the output more than makes up for the mess.

If you're thinking of making the leap to a resin based personal printer I'd love to follow your journey — please get in touch!

Fom the Kickstarter page:

"DIY 3D Printers based upon the Fused Deposition Modeling (FDM) concept simply can not match the higher resolution capability of the B9Creator. We utilize a powerful Deformable Mirror Device (DMD) projector to shine a 1024 x 768 pixel image onto a layer of photo-initiated polymer resin. The result is a quick solid cure of the entire layer in one operation. The layer thickness is typically 100 microns but your model can be sliced even thinner if you need even higher resolution. Note that 100 microns is 0.1 mm or about 0.004"

How about speed? Anywhere from 12-20 mm per hour and that's independent of the object's x-y density (unlike FDM which slows down as the x-y fill density increases).

"But how much does that resin cost?" The Eiffel Tower model pictured here weighs about 12 grams. Our resin costs about 10 cents per gram, making the material costs to print the Eiffel Tower just $1.20!"