Coated 3D printed parts produced by Horizon Microtechnologies have successfully passed outgassing testing in accordance with the ECSS-Q-ST-70-02C standard for screening of space materials.

This standard is a key requirement for materials and parts used in space. Horizon Microtechnologies believes the development is 'a significant step' in validating its proprietary metallisation process for precision- and micro-additive manufacturing (AM) polymer parts.

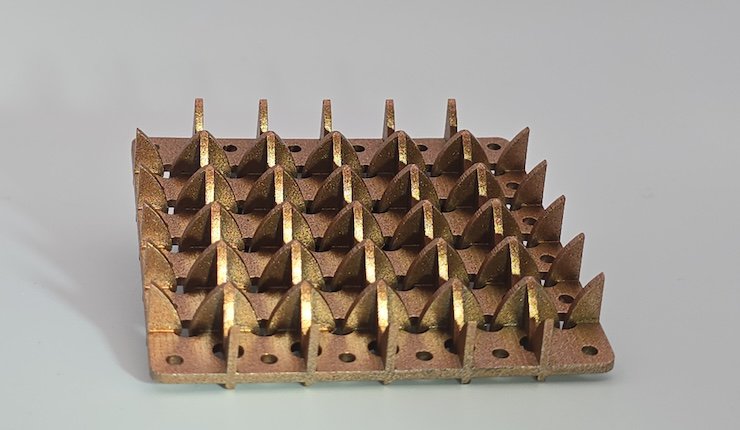

The Horizon Microtechnologies approach - combining precision 3D printing with advanced coating and metallisation technologies - enables the creation of highly functional microscale components, such as next-generation antenna structures in RF and microwave applications. This process has come through outgassing tests which evaluated the coated plastic micro-AM parts under thermal vacuum conditions. Outgassing poses a severe risk in space applications because the effect is more pronounced and potentially more harmful due to the vacuum environment. It can lead to contamination of sensitive instruments and degrade material performance, especially coating adhesion.

The specimens were exposed to 125°C, in line with the testing standard, in a vacuum range of 10⁻⁶–10⁻⁷ mbar for 24 hours. Parts were weighed immediately before and after the process, as well as 24 hours later, to determine the amount of volatile content released and reabsorbed by the parts.

Testing also considered the amount of material that condensed or otherwise collected on a test plate held at 25°C and located close to the samples, in order to see whether the tested materials could lead to contamination of neighbouring components. This is quantified as Total Mass Loss (TML), Recovered Mass Loss (RML), and Collected Volatile Condensable Material (CVCM), respectively. The results were said to show that TML was 0.354%, RML was 0.166% and CVCM was 0.000% - all within the acceptance limits defined by ECSS-Q-ST-70-02C for materials intended for spacecraft (RML <1.00% and CVCM <0.10%).

“This result is significant for Horizon as further validation that our combination of 3D printed material and coating delivers the level of reliability and material stability needed for applications where failure is not an option,” says Andreas Frölich, CEO of Horizon Microtechnologies. “Historically, coatings on 3D-printed parts have been viewed with scepticism due to challenges such as outgassing, delamination, and surface fragility. With this test, we’ve demonstrated that these barriers can be overcome.

“This milestone is part of our broader strategy to validate our technology across all relevant stress domains, thermal, mechanical, and environmental. We are building a track record of success that we believe will fundamentally shift how engineers think about coating technologies for polymer AM parts.”

Having come through outgassing testing successfully, Horizon will now continue its qualification programme with vibration, atomic oxygen, and radiation tests.