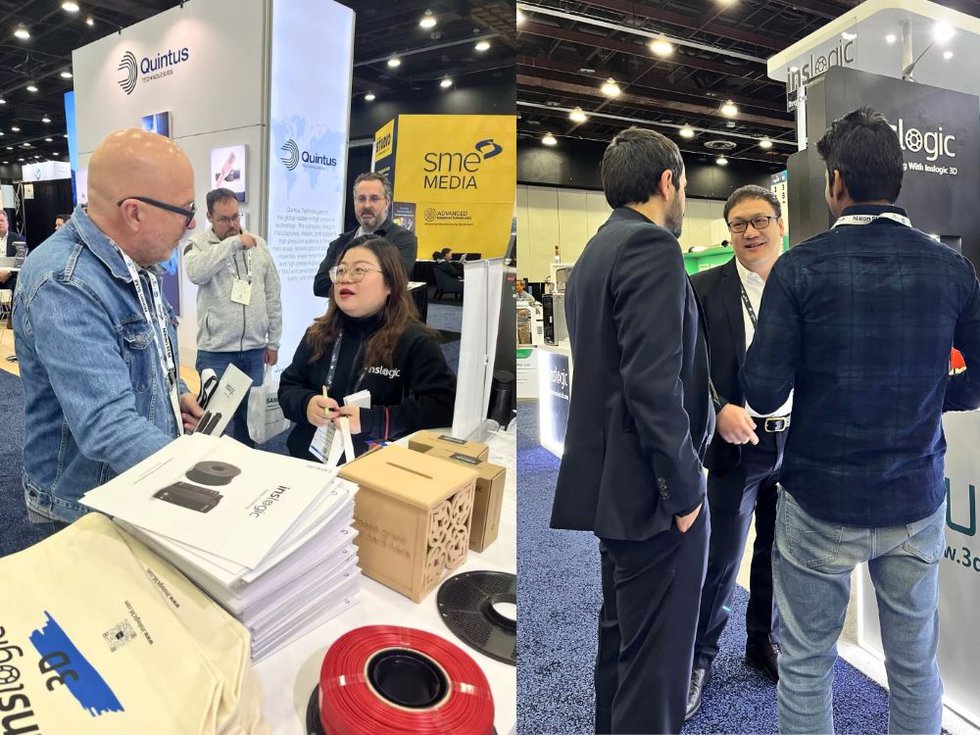

At RAPID + TCT, Inslogic showcased its advanced 3D printing materials for functional prototyping, end-use production, and demanding mechanical environments. The company’s solutions boast high performance and enhance mechanical properties for broader applications.

“This year’s RAPID + TCT has been an unforgettable experience, and Inslogic is excited to continue its commitment to supporting the 3D printing community with quality, high-performance, reliable materials produced for real-world applications. Inslogic will be your trusted partner for your projects.”

At the additive manufacturing event, Inslogic presented a wide variety of advanced materials for prototyping, manufacturing, and testing applications. Said materials offer reinforced mechanical properties and improved reliability, allowing them to handle more complex applications. Among the company’s exhibited solutions were its advanced thermoplastics and photopolymers.

Filaments:

- PEEK: Offering exceptional mechanical strength and resistance to heat and chemicals.

- PA12-CF: Boasts carbon fibre reinforced for improved strength, reduced weight, and low moisture sensitivity.

- PA6-CF: Providing excellent heat resistance up to 209°C.

- PC-ABS: Combines the strengths of polycarbonate and ABS, providing heat resistance, impact resistance, and flexural strength.

- PA6-GF25: Glass fibre reinforced for greater strength, rigidity, and heat resistance.

- ABS FR V0: UL94 V-0 certified with flame-retardant and self-extinguishing properties.

- TPU 90A: A tough elastomer with high elongation at break and superior tear strength, ideal for creating flexible, resilient parts.

Resins:

- High temp resin: Can withstand temperatures up to 300°C and is engineered for parts requiring high thermal stability.

- Flexible 70A resin: Enhanced resistance to bending and compression, able to withstand repeated flexing without breaking down.

Also at Inslogic’s stand was its 3D printed puzzle cube. This addition helps to demonstrate the company’s material strength and quality while also showcasing its abilities in terms of precision and durability.