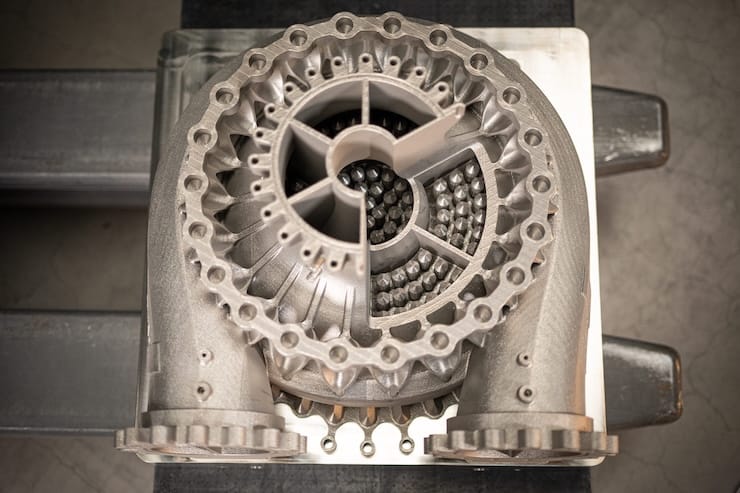

A 2000kN full-flow staged combustion rocket engine injector head designed by LEAP 71 has been additively manufactured by Nikon SLM Solutions.

The component is a critical element of the LEAP 71 XRB-2E6 methane/liquid oxygen rocket bell nozzle engine that the company announced was under development in April. It was printed using Nikon SLM's NXG 600E metal additive manufacturing system and marks an 'important milestone' of a collaboration that commenced more than two years ago.

At 600 mm in diameter, LEAP 71 considers the object to be one of the 'largest and most complex 3D printed spacecraft parts ever produced.' LEAP 71's Noyron Large Computational Engineering Model, which was deployed for the development of the 5kN rocket engine LEAP 71 successfully tested last year, was used to design the component.

Nikon SLM Solutions printed the part in IN718, an aerospace-grade material that can withstand the heat loads and pressures of a full-flow staged combustion (FFSC) engine cycle. FFSC is considered the most efficient way to convert the propellant's chemical energy into thrust, hence LEAP 71's focus on developing such an engine. With a thrust of 2 Meganewton, LEAP 71 is also targeting a level similar to that of engines powering the world’s latest generation of heavy-lift launchers.

Exclusive: Behind the scenes at world first hot fire test of computationally engineered rocket engine

Practical testing of the engine is slated for Q4 2027, with LEAP 71 describing the schedule between now and then as 'aggressive' to validate the industrial processes needed to manufacture the engine. That will require, according to the company, key partnerships and some of the largest metal 3D printers in the world. Metal additive manufacturing is considered by LEAP 71 to be the most optimal way of enabling the design freedom that Noyron needs to create complex and efficient engines, while also allowing the engine to be designed as one monolithic part. This will eliminate the need for assembling hundreds of standardised parts and potentially improve reliability and production timelines.

Christoph Wangenheim, Head of Additive Material Products & Development at Nikon SLM Solutions, said: “When LEAP 71 came to us to discuss the production of a key element of one of the world’s most advanced space propulsion systems, we knew it would be a challenge we couldn’t resist. We worked closely with LEAP 71 on incorporating essential manufacturing parameters into their Noyron system and fine-tuning the interplay between the steps of the process chain. As a result, we were able to not only print the intricate structure reliably on the NXG 600E, but also in the record time of less than four days using our IN718 PROD parameter set — key to making production economically viable and enabling rapid iteration during qualification.”

“We are happy to collaborate with Nikon SLM Solutions on this ambitious project. With their legacy as one of the original inventors of metal 3D printing, we couldn’t hope for a better partner on this journey,” said Josefine Lissner, Co-founder and CEO of LEAP 71 and principal architect of the Noyron Large Computational Engineering Model. “The NXG’s 12-laser system brings down manufacturing time to a level that enables the rapid turnaround we need to take full advantage of the iteration speed our paradigm enables.”

The XRB-2E6 system is intended as a reference design, with customer engines computationally derived for differing target specifications. The XRB-2E6 injector head will be showcased at Formnext by Nikon SLM Solutions (Hall 12.0, D119).