The Light Aircraft Association, the UK’s principal representative body for amateur-built and vintage light aircraft, is to take two safety actions concerning the use of 3D printed parts after a Cozy Mk IV crashed at Gloucestershire Airport earlier this year.

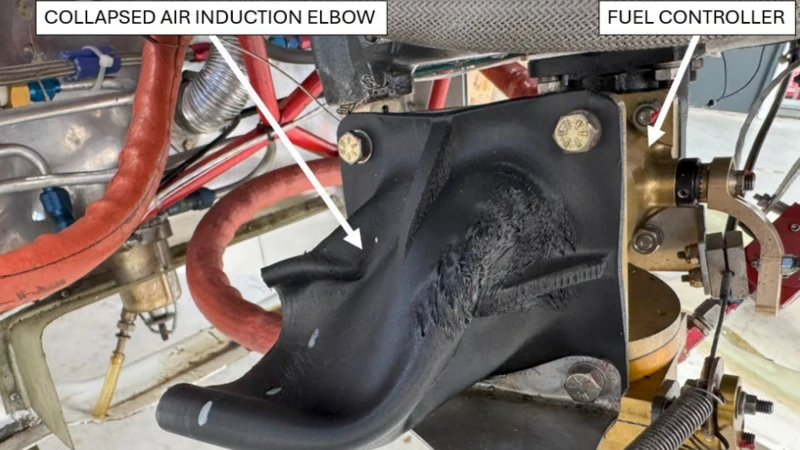

A 3D printed air induction elbow is believed to have 'softened and collapsed' when exposed to heat from the engine as the aircraft took flight. The engine lost power on the aircraft’s final approach on the runway, causing the aircraft to collide with the ILS localiser antenna array, a ground-based system that provides horizontal guidance to aircraft approaching to land. Though the aircraft can carry four passengers, the pilot was the only person on board and suffered only minor injuries. The aircraft was destroyed.

The Air Accidents Investigation Branch (AAIB) has suggested in its report of the incident that the induction elbow was made of ‘inappropriate material’. The part was purchased at an airshow in the United States and installed by the aircraft owner while modifying the fuel system of the aircraft. Per the AAIB report, the owner of the aircraft understood that the part was printed using CF-ABS filament and exhibited a glass transition temperature of 105°C.

FULL REPORT: AAIB investigation to Cozy Mk IV, G-BYLZ

Since the conventionally manufactured part, which was manufactured by laminating four layers of bidirectional glass fibre cloth with epoxy resin, had a glass transition temperature of 84°C after post-curing, the owner is said to have been satisfied that the component was fit for use. However, AAIB’s report says two samples of the air induction elbow were subjected to testing using a heat-flux differential scanning calorimeter to determine their glass transition temperature. The measured glass transition temperature was 52.8°C for the first sample and 54.0°C for the second sample. The exact material composition of the 3D printed elbow was not determined.

Additionally, the AAIB report says that a review of the design of the laminated induction elbow featured a section of thin-walled aluminium tube at the inlet end of the part where the air filter is attached, providing a degree of temperature-insensitive structural support. The 3D printed induction elbow did not include a similar section of aluminium tube at the inlet end. A forward-facing air filter had been clamped onto the forward end of the elbow, but this is believed to have detached as it was found loose in the lower engine cowling.

The AAIB report also says that a parts list supplied to LAA Engineering for the fuel system modification did not include the 3D printed induction elbow, and the organisation was therefore not able to independently assess its airworthiness.

Moving forward, the LAA intends to publish an ‘LAA Alert’ regarding the use of 3D printed parts. All LAA inspectors will receive this alert and it will also be referenced in the Engine Type Acceptance Data Sheet (TADS) for all engine types, ensuring it is used as a reference each time the Permit to Fly for an LAA aircraft is revalidated.