Last week SpaceX’s unmanned Dragon capsule safely splash landed in the Pacific Ocean five and a half hours after it had detached from the International Space Station, seeing as it took me the same amount of time to drive 30 miles the previous evening that is pretty impressive.

Whereas other robotic spacecrafts are designed to burn up in the earth’s atmosphere the Dragon Capsule is the only operating robotic spacecraft that can return supplies to earth.

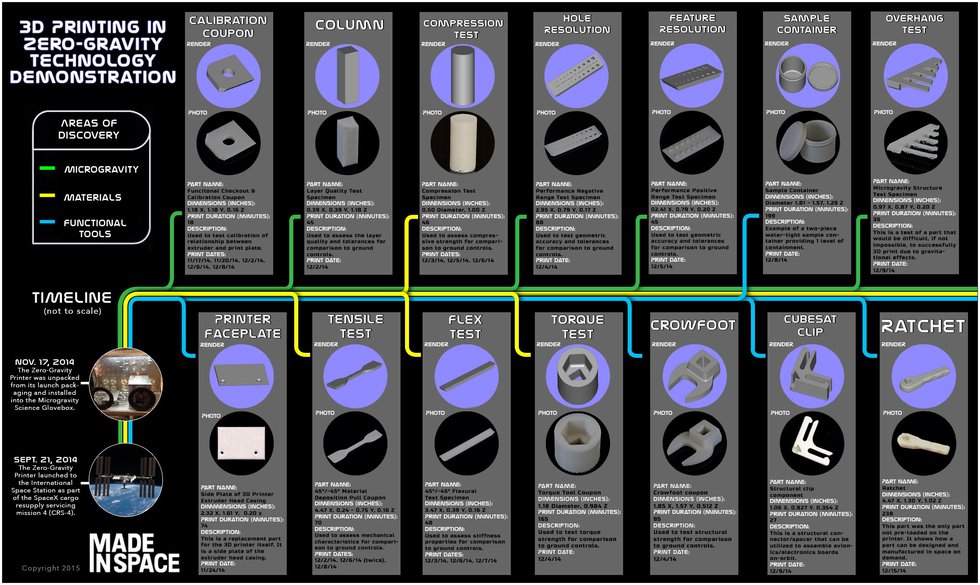

Amongst the 1600 kilos of cargo that returned to earth were some particularly important scientific research projects; zebrafish, which are to be analysed for muscle deterioration because of the weakening astronauts suffer during time in space; along with some tools and parts 3D printed on the ISS space station.

Made In Space’s 3D Printer, housed in the microgravity glove-box on-board the ISS, first made its way to the cosmos on Dragon’s previous mission and it was anticipated that only parts designed as part of the pilot programme would make its way back on this visit for testing on earth.

However, the goal of the mission – to create spare parts and tools in space on-demand – was expedited as a request was made for a ratchet wrench to ground control was intercepted by Made In Space, who decided to try their theory out for real.

The wrench designed on earth by Made In Space, uplinked to space by NASA and 3D Printed by ISS Commander Butch Wilmore has now returned back to earth to be put through its paces to see if there is any difference in parts 3D printed in microgravity to those printed on earth.

"For the printer's final test in this phase of operations, NASA wanted to validate the process for printing on demand, which will be critical on longer journeys to Mars," explained Niki Werkheiser, the space station 3-D printer program manager at NASA's Marshall Space Flight Center in Huntsville, Alabama.

In total since its launch in September the Made In Space printer has printer 25 parts, 14 of which are unique. Incredibly, especially for extrusion-based 3D printing, there has not been a single failed print. Perhaps these 3d prints in microgravity may provide some insight into improving their earthly counterparts?