Materialise has announced the addition of PEEK (polyetheretherketone) to its portfolio of cranio-maxillofacial (CMF) implants.

Complementing its titanium 3D printed implant offering, surgeons using the Belgian additive manufacturing (AM) company's same validated 3D planning workflow for patient-specific reconstruction procedures will now be able to select from either titanium or PEEK, depending on the needs of the patient.

"Personalisation isn't just about material choices but about the precision of the planning process and the reliability of execution," said Maarten Zandbergen, Market Manager at Materialise. "Our clinical engineers work hand in hand with surgeons to design each implant, and that collaborative approach remains constant whether the case calls for titanium or PEEK. What changes is the surgeon's freedom to choose; what stays the same is the peace of mind that comes from a proven, end-to-end process.”

PEEK is permeable to radiation and X-rays, which makes it a preferred choice by many surgeons for cranial reconstruction, facial contour restoration and onlay applications. Each PEEK implant will be manufactured via milling in Europe under an EN ISO 13485 certified quality management system by Materialise manufacturing partner Ad Mirabiles within a 72-hour window following surgical plan approval. The custom-made PEEK implants are now available to surgeons across Europe (excluding Switzerland), where Materialise CMF solutions are established.

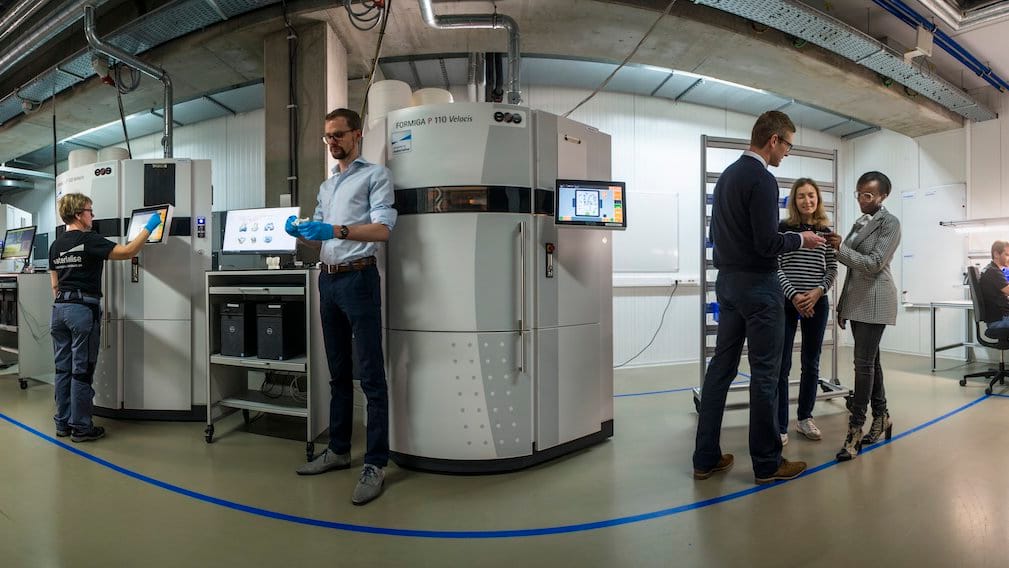

Materialise claims to produce around 280,000 personalised 3D printed instruments and implants per year, including CMF products. In 2023, the company expanded its CMF production beyond its facility in Belgium with the launch of a medical 3D printing facility in the United States, designed to speed up the delivery of patient-specific implants.