MetalPrinting Inc. has presented its Gauss MT90 metal 3D printing system at this week's TCT Japan trade fair.

The South Korean company debuted the machine at CES 2026, where it won a CES Innovation Award.

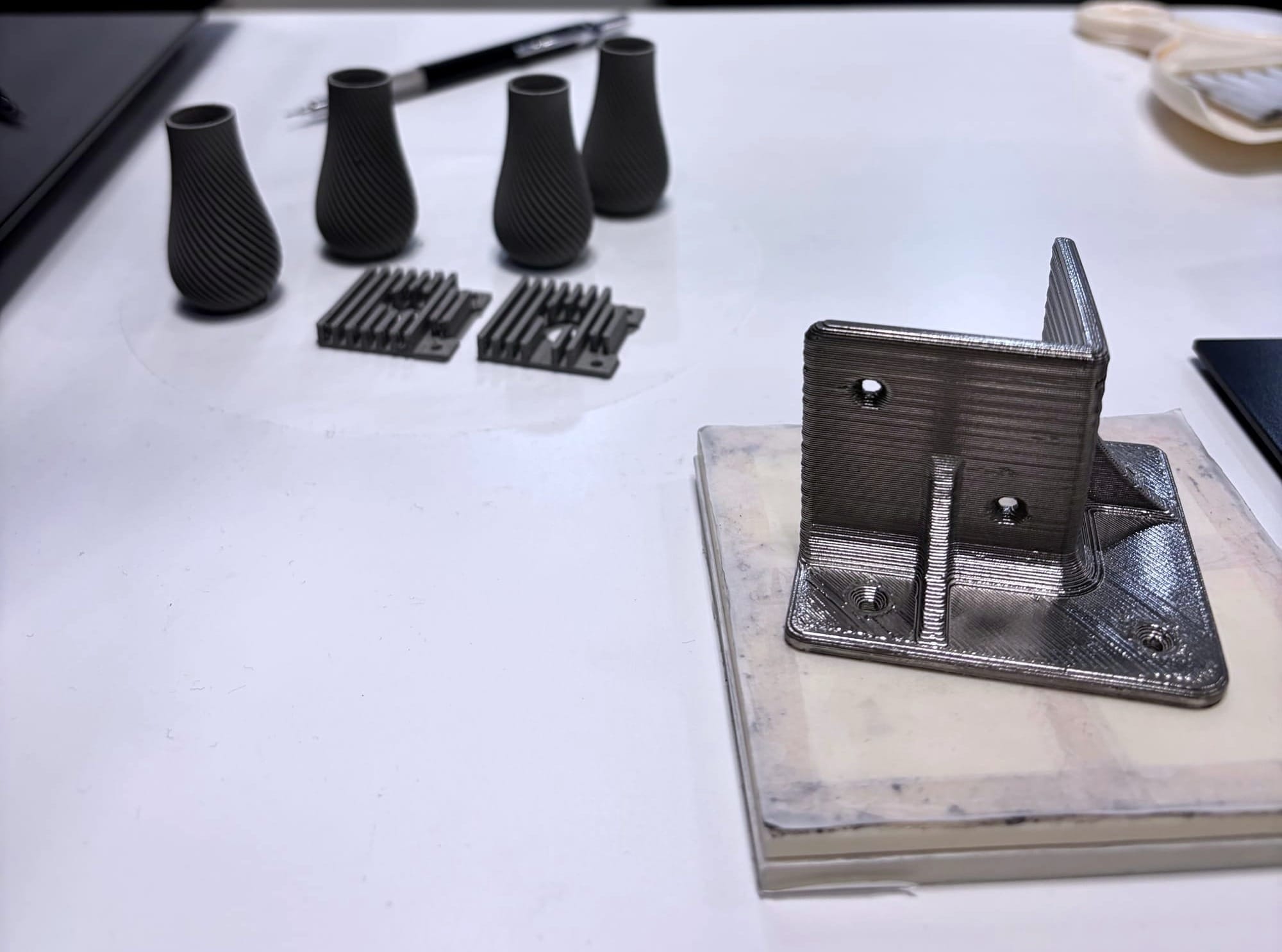

Utilising metal paste or ink, the machine works by depositing material through a nozzle to build parts layer by layer. Printed parts are then heat-treated in a furnace or sintering oven.

MetalPrinting Inc. says the Gauss MT90 is suitable for industrial use, prototyping and small part production, and also describes it as 'office-friendly'. Since no powder is used in the process, the company is positioning its Gauss MT90 machine as a safer alternative to laser powder bed fusion and binder jetting processes. It is being marketed at a price point of 35,000 USD, which the company expects to be another advantage of competing products.

Having initially started as a materials development company in 2018, MetalPrinting Inc. uses its own proprietary materials, offered under the GAUSS Ink brand. At TCT Japan, the company presented printed components made from stainless steel and copper, with a wider range of metals said to be available. Materials development, the company told TCT, remains its main technical focus.

MetalPrinting Inc. is led by CEO Daesan Kim, who has been engaging with visitors to the company's stand at TCT Japan, and noted the event provided an opportunity for the company to present its technology internationally and expand its presence beyond Korea.