COBRA Golf has unveiled two new 3D printed iron models within its 3DP commercial product line.

The 3DP MB and 3DP X models follow the 3DP TOUR, the company's first commercial in-line 3DP iron, which combines a blade shape with game-improvement forgiveness tailored for a range of players from Tour pros to mid-handicappers.

Completing the 3DP iron family, COBRA says the two new models allow golfers of all abilities to experience the 'game-changing benefits of 3D printing.'

Similar to the Tour-validated 3DP TOUR, the MB and X models use 3D printing to improve the performance, look and feel while providing more 'forgiveness'. They are also said to deliver enhanced distances of much larger designs.

Per COBRA, the 3DP MB shaping is based on the prototype MB club head made for American pro golfer Max Homa, which has slightly more offset and a thinner topline than the KING MB. The X model is similar in size and shape to Cobra’s KING TEC X iron but features 'a level of forgiveness that exceeds that of Cobra's DS-ADAPT MAX super game improvement irons.'

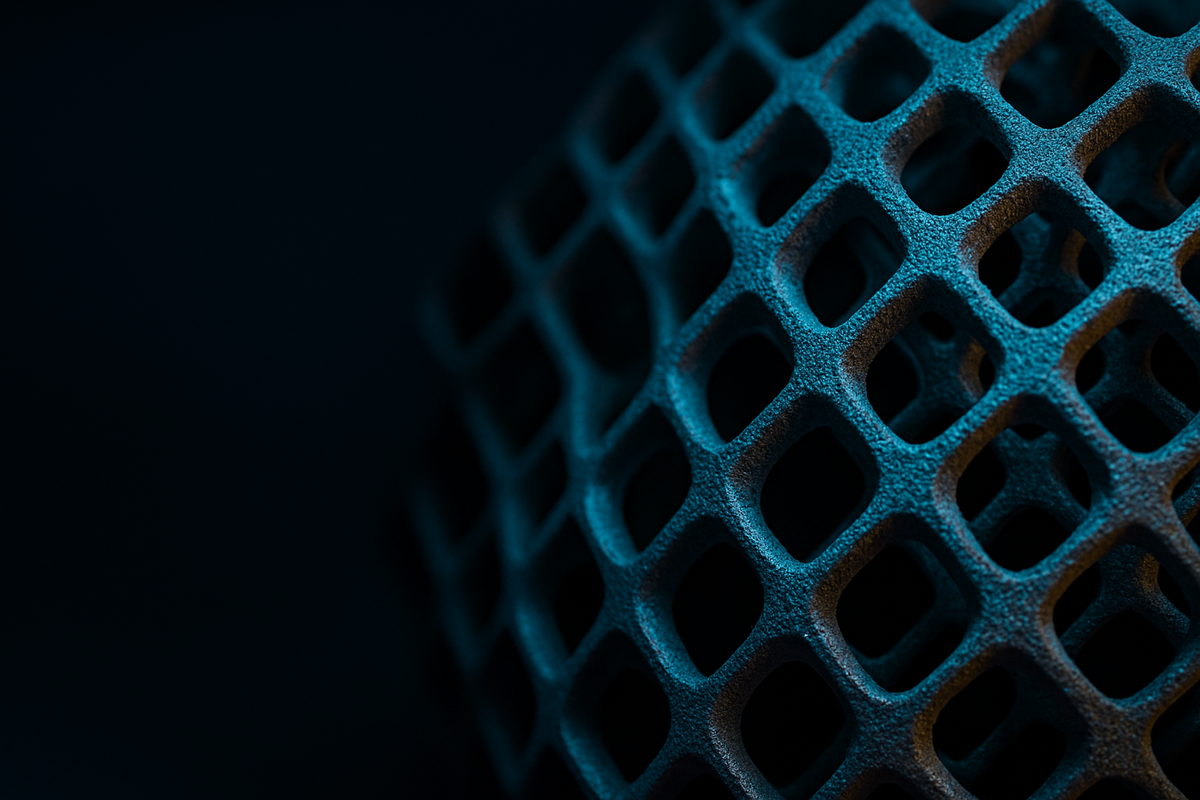

The 3DP MB is 3D printed with an internal lattice core that tunes acoustics for soft, forged feel, and repositions weight in the heel and toe with tungsten to achieve a high MOI and lower CG. COBRA considers it to be the 'most forgiving blade on the market today' and says its signature shape features subtle refinements to Cobra's KING MB, including a slightly thinner topline and increased offset.

COBRA's 3DP X, meanwhile, has been designed for 10-20 handicappers looking for 'super game-improvement performance and high launch' in a sleek package. Like the other irons in Cobra’s 3DP family, each X iron is fully 3D printed from 316L stainless steel using a Direct Metal Laser Sintering process and features an internal lattice structure for weight savings and improved weight distribution. For enhanced forgiveness and higher launch, the 3DP X irons also feature tungsten weights in the toe and hosel, increasing MOI and stability on off-centre hits.

Unlike many game improvement and distance irons, Cobra’s new 3DP X irons feature a one-piece design without the addition of a face insert. Instead, the internal lattice structure supports the thin face design enabling performance and forgiveness without sacrificing feel.

“We’re excited to offer these two new innovative iron models that build on the tremendous success of our 3DP Tour irons,” said Ryan Roach, Director of Innovation at COBRA PUMA GOLF. “With the addition of the MB and X, we now have a 3D printed model that can fit the vast majority of players, allowing just about any golfer to benefit from the performance advantages of 3D printing technology.”

“Cobra Golf has always been driven by innovation,” added Dan Ladd, President of COBRA PUMA GOLF. “The fact that we are the first OEM to offer a full range of 3D printed irons that exceed the performance of comparable, traditionally made irons clearly shows our level of dedication to making the very best performing gear in golf.”

MSRP for the 3DP MB and 3DP X will be $1,980 for a six-piece configuration in RH and LH with KBS steel shafts ($-Taper 110 on MB, Tour Lite on X) and Lamkin Crossline grips offered in stock set configurations. A Gap Wedge is available through custom order for all 3DP iron sets, and a 3-iron is also available for the MB.

The new 3DP MB and 3DP X irons will be available for pre-sales on January 6th, 2026 and at retail on January 9th, 2026.