3D printing custom made car parts may seem a reserve for the rich and famous, but a blogger on Opposite Lock shows how they designed and replaced a knob on their dashboard for $10.

Now retired host of the Tonight Show, Jay Leno, is probably the most famous exponent of combing 3D printing with custom made car parts. In his online series Jay Leno’s Garage he’s often seen showing off his NextEngine 3D scanner and Dimension 3D Printer.

What Leno does is scan and recreate parts for obsolete vehicles, 1907 White Steamers or vintage Bugattis. He’s often heard saying, “thanks to this technology no car is obsolete anymore”. But what about those of us with a normal Fords or Toyotas and without access to multi-thousand dollar equipment? How can we use this tech?

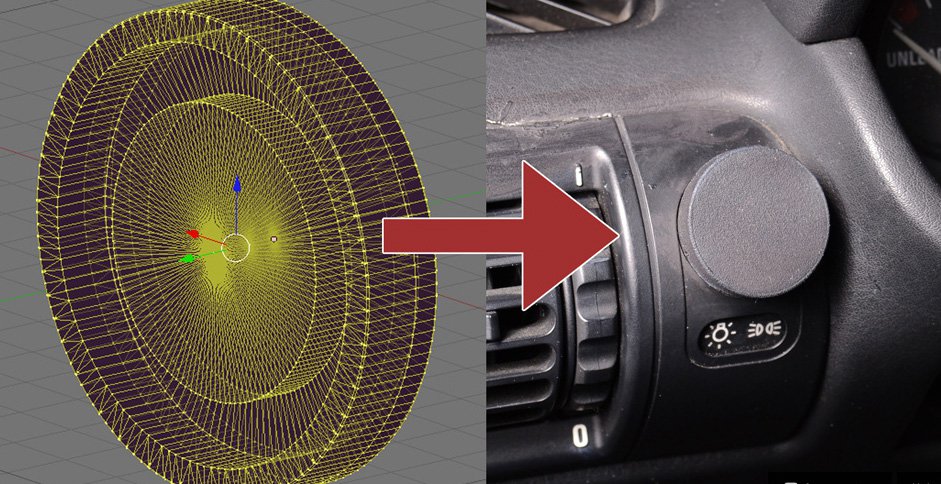

A post on leading petrolhead website, Opposite Lock, excellently details the use of free software Blender to 3D model a missing working part to control their headlights. The blogger, Huntsville-AL, then sent his model off to Shapeways paid $10 and hey presto! A week later he had a working replacement for his car (see the pic above).

When people say “The Internet of Things” this is the sort of thing we can envisage becoming ultra popular, repositories for DIY fixes around the home and your car, it seems an absolute perfect match for this technology.