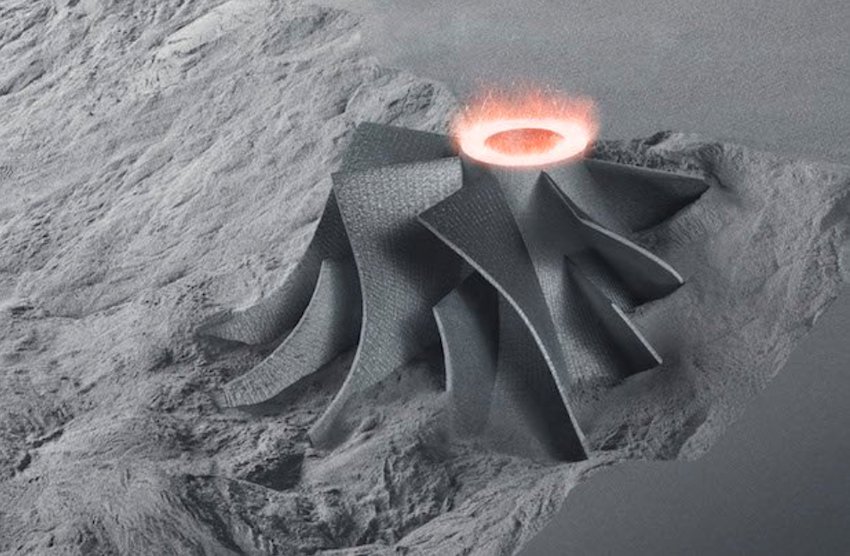

Aibuild launches Finite Element Thermal Simulation for DED and large-format polymer 3D printing

By

TCT Team

/

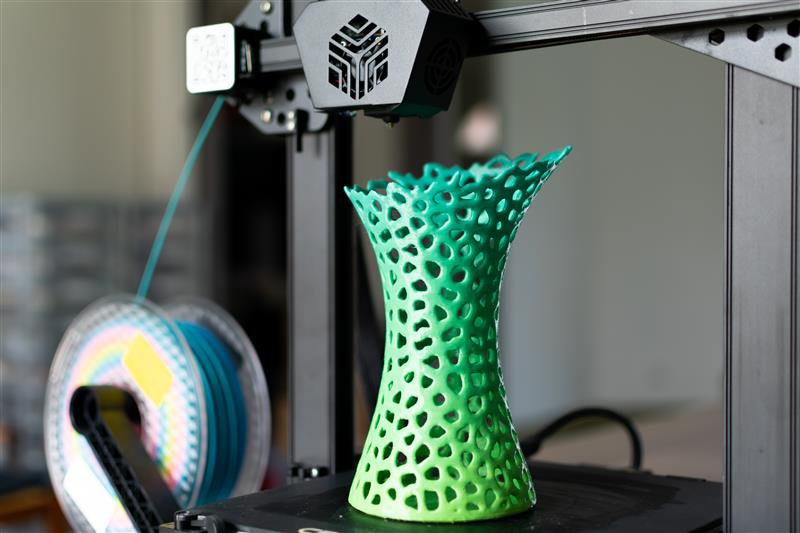

Firestorm Labs secures exclusive distribution rights of HP's Multi Jet Fusion technology in mobile and field-deployable environments

By

Sam Davies

/