Polymaker has announced the launch of its PolySonic range of filaments designed to help enable high-speed extrusion 3D printing.

The company introduced two new PolySonic materials at the TCT Asia event in Shanghai, which runs from September 12-14.

Its PolySonic PLA and PolySonic PRO materials are said to allow a higher volume of parts to be printed per hour without compromising on printing characteristics or the mechanical strength of the printed part. With PolySonic PLA (which Is initially available in five colours), Polymaker says users will be able to build printing profiles over 300mm/s with superior print characteristics. PolySonic PLA PRO (available initially in two colours), meanwhile, is compounded with impact modifiers that produce ductility similar to ABS and stiffness that outperforms ASA and PETG.

“The latest generation of 3D printers have set a new benchmark for fast printing,” commented Dr. Xiaofan Luo, founder of Polymaker. “But materials are still the missing link. PolySonic is Polymaker’s answer to the new era of high-speed FFF printing.”

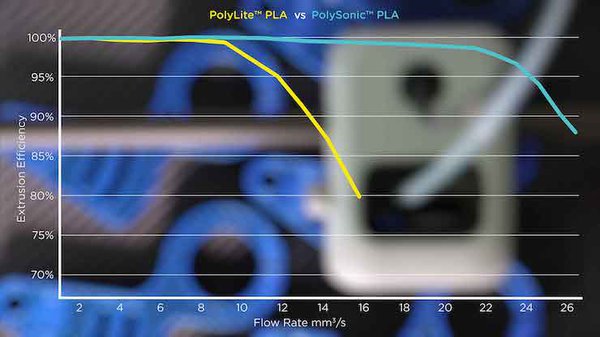

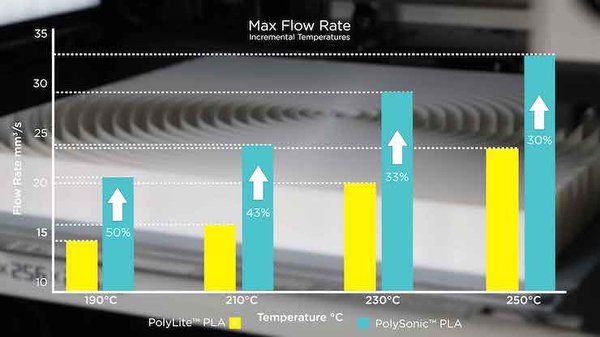

When embarking on the development of the PolySonic family of materials, Polymaker defined extrusion, forming and mechanical properties as the three crucial aspects to classify a material as a ‘high-speed’ filament. As the filament passes through the nozzle at higher flow rates, there is less time for heat to transfer into the filament, which can lead to under extrusion. Polymaker claims, however, that PolySonic materials exhibit a wider extrusion window when compared to regular PLA filaments, producing a 40% increase in volumetric flow rate at the same printing temperatures. That boost in extrusion efficiency thus allows users to build profiles with higher printing speeds with less chance of under-extrusion.

The forming of the material occurs after the filament leaves the nozzle, and as auxiliary part cooling fans are becoming more common, the filament’s ability to rapidly cool and form on the previous layer is the determining factor to final print quality. Polymaker scientists are said to have optimised the rheology of the PolySonic so that it can transition from fluid to solid with near-zero shrinkage, helping to produce crisp corners, fine details and steep overhangs while still extruding at high volumetric flow rates.

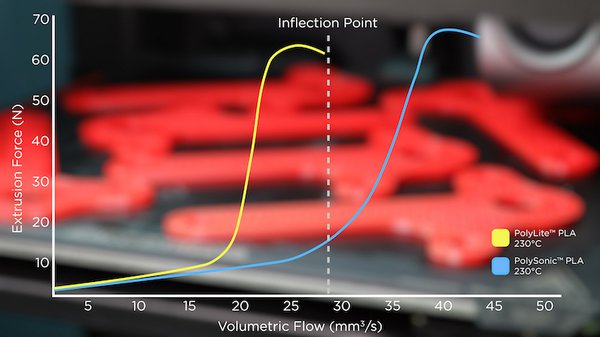

As the flow rates increase, micro-slipping can occur between the filament and extruder gears, leading to under extrusion on printed parts because the filament has not fully melted inside the nozzle. Under extrusion means less plastic is filling the voids between the perimeters, layer starts, infill and top surfaces making the part less homogenous and allowing for more potential failure points inside the matrix, a greater chance of delamination under stress, and weaker part strength in the X-Y axis. Improper heating of the filament can also mean layer adhesion is greatly reduced, dramatically impacting part strength in the Z-axis direction.

Prior to launching the PolySonic range, Polymaker tested specimens under two printing speeds to compare the final part strength: The classic printing speed of 46.5mm/s and a high speed of 300mm/s. Specimens were printed with the same amount of walls, top/bottom surfaces, infill and printing temperature. Polymaker suggests that its PolySonic PLA shows only a 6% drop in mechanical properties when printing at high speed compared to the classic test specimen, while its PolyLite PLA showed a 24% drop when the speed is increased.

Polymaker is exhibiting at TCT Asia from Stand H57.

Additive Insight by TCT · #144 TCT Asia 2023: What to expect from China's leading additive manufacturing event