Rapid Fusion is set to lead the manufacturing element of a £700,000 maritime vessel design and production project backed by UK Government.

The additive manufacturing firm will join Compute Maritime, BYD Naval Architects, Siemens Digital Industries Software and the University of Southampton on the Clean Maritime Demonstration Competition initiative.

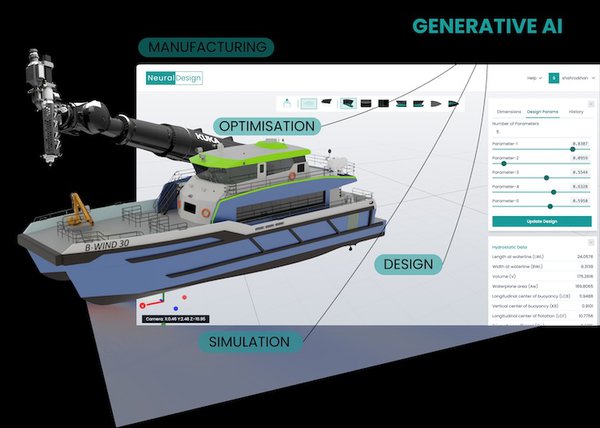

Operating under the 'GenDSOM' moniker, the initiative will aim to advance maritime design by leveraging generative artificial intelligence (AI)-driven approaches and building foundation models, thereby significantly reducing the design-to-manufacturing cycle and enabling high-performing, innovative solutions.

The approach brings together the complementary expertise of the consortium partners: generative AI (Compute Maritime), design (BYD Naval Architects), simulation (Siemens), optimisation (University of Southampton) and manufacturing (Rapid Fusion). This integrated development will be powered by the advanced compute capabilities of HP Z Workstations & Solutions.

A crew transfer vessel (CTV) provided by BYD Naval Architects - critical to supplying staff to the offshore wind sector - will be the test case and focuses on optimising hull design with hydrofoils produced in large format additive manufacturing using Rapid Fusion’s Apollo robot system.

“Confronted by multifaceted challenges, the maritime industry urgently requires truly evolved, smart design frameworks that balance sustainability with operational and economic viability,” explained Shahroz Khan, CEO of Compute Maritime, a London-based deep-tech company bringing intelligence to the core of the global shipbuilding industry.

“The transformation of ship design is no longer optional - it is a critical survival strategy in an industry historically anchored in tradition. That’s why this project is so important, and we firmly believe that through the power of NeuralShipper (our generative AI copilot) and the expertise of our consortium partners we can achieve a 10% reduction in design costs, 20% faster design cycles, and a 50% increase in overall design efficiency.”

According to the partners, GenDSOM will respond directly to the UK's 2025 Maritime Decarbonisation Strategy, which targets emissions reductions of 30% by 2030 and 80% by 2040 for domestic maritime.

Rapid Fusion will be using its Apollo 3D printing solution to support the production of large components and moulds.

Martin Jewell, Chief Technical Officer at Rapid Fusion, commented: “Additive manufacturing has expanded design freedoms and is rapidly gaining traction for both small components and large structures, including hull forms, in the world of maritime. Yet scalability remains constrained. GenDSOM is going to adopt a modular strategy, breaking designs into manufacturable subcomponents compatible with both traditional and AM processes.

“Our manufacturing-aware approach ensures designs remains manufacturable while integrating constraints, building envelope limits, support structures, tolerance stacking and material compatibility for instance. All of this will ensure innovative, efficient, and production-ready solutions, while enabling decarbonisation across the design-to-manufacturing lifecycle.”

The project is set to take place over the next seven months.

Additive Insight by TCT · #224 'We either innovate or we die.' - Rapid Fusion on its Medusa hybrid manufacturing platform