Replique is expanding its collaboration with Alstom worldwide.

The company will now serve as a global supplier for numerous projects and subsidiaries in locations such as Singapore, Brazil, Australia, France, Italy, Germany, Thailand, and Spain.

Initially, Alstom tapped Replique's digital manufacturing network to provide additively manufactured door stoppers and tank caps, with the success of these components leading to a deep collaboration between the two entities. Over time, Replique's manufacturing capacity has been leveraged to produce parts in volumes in the lower five-digit range. These parts – made from materials ranging from stainless steel to flame-retardant plastics – are said to be in daily use across railway operations, with all of them meeting Alstom’s specific testing and qualification requirements.

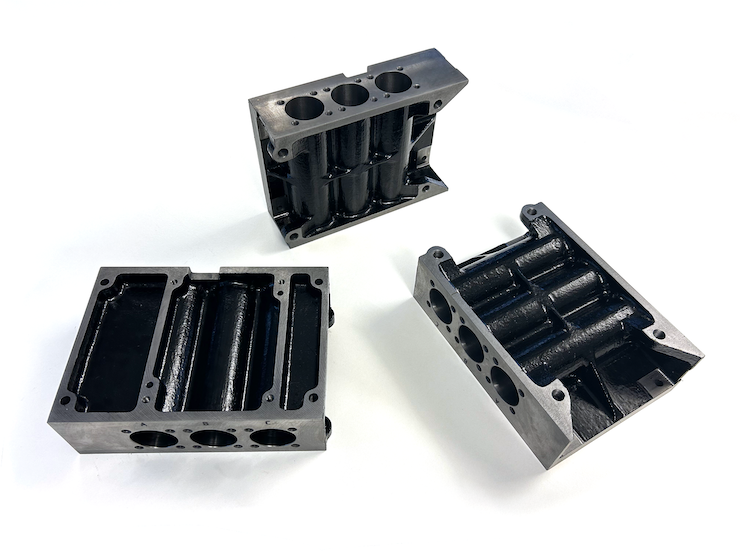

Among the successful applications to be enabled by Replique include a replacement impeller parts for a metro solution cooling unit in Asia and 3D printed casting moulds to secure long-term availability in Italy.

Additionally, for a new series of Alstom trains, Replique is supplying branding plates worldwide.

“Replique doesn’t just deliver the components; it ensures consistently high quality across the globe, which is especially crucial for series production,” said Lorenzo Gasparoni, Alstom 3D Printing Program Manager. “Replique also completed the entire series approval process, including First Article Inspection and First Article Mount – with excellent results.”

“We are proud to provide Alstom with global solutions that make their parts supply more efficient and flexible. Our components are used in series production, and each project highlights the diverse challenges of parts procurement while motivating us in our vision of a globally connected, sustainable, and efficient supply chain,” added Dr. Max Siebert, CEO and Co-Founder of Replique.