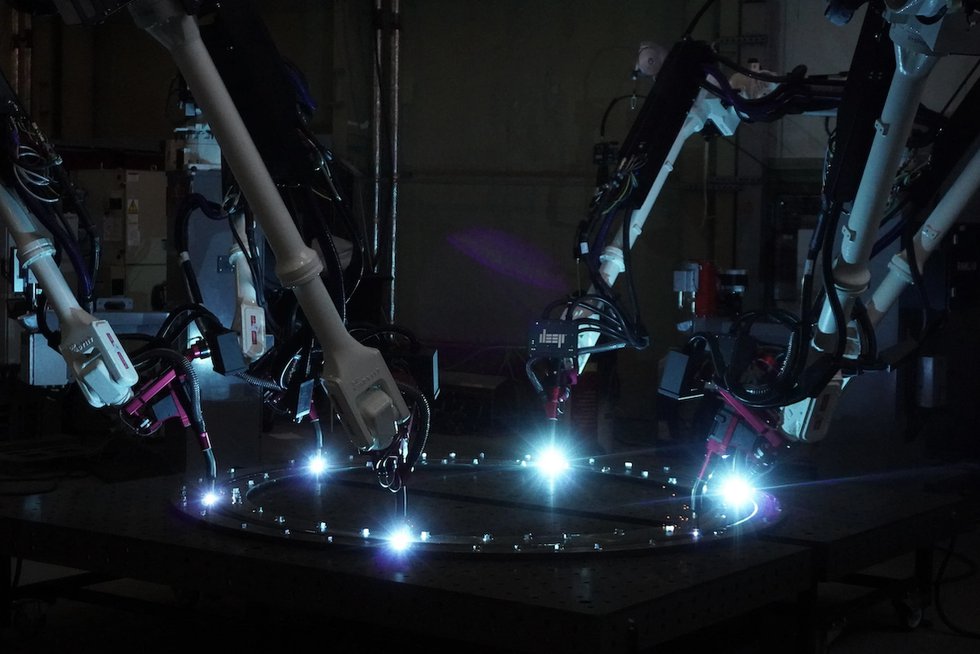

UK-based casting and forging production company Sheffield Forgemasters has announced the launch of its in-house hybrid additive manufacturing system.

Housed in a 14m x 8m x 5m enclosure, the large-format robotic system combines CEAD Flexbot 3D printing with milling across two tables - one fixed, the other rotating - to create complex casting patterns. It is said to be capable of printing up to 60kg of material per hour, including fibre-reinforced polymers.

The new capability is expected to bring “significant benefits” to the 200-plus-year-old company - which started as a small blacksmith forge in the 1750s - according to Michael Howson, Senior Development Engineer, Advanced Manufacturing Capability.

“This system provides our Patternmakers with an additional tool that, through autonomous operation, will allow staff to work on complementary activities during shifts and enable production to continue outside standard working hours, improving overall efficiency and capacity,” Howson said in a press release. “The new facility will reduce costs, shorten lead times for pattern production, and in turn improve delivery times for castings.”

The introduction of new digital capabilities is also thought to be helping to cultivate the next generation of pattern makers, and support more sustainable practices through reduced material waste and recycling.

Jason Barker, Founder/CTO at CNC Robotics, which partners with CEAD for UK distribution and maintenance, said: “This hybrid large-format additive and subtractive capability isn’t just a technological upgrade, it’s a step-change in how manufacturers like Sheffield Forgemasters can operate. By digitising and automating aspects of traditional pattern manufacturing, the CEAD Flexbot enables faster turnaround, higher repeatability, and greater design freedom.