SLM Solutions has unveiled its latest additive manufacturing technology today, promising “support-free” 3D printing with reduced cost per part and increased design freedom.

It’s called Free Float, a new software which, according to AM pioneer Dieter Schwarz per today’s launch event, “will have a big impact on the industry and the usage of additive manufacturing.”

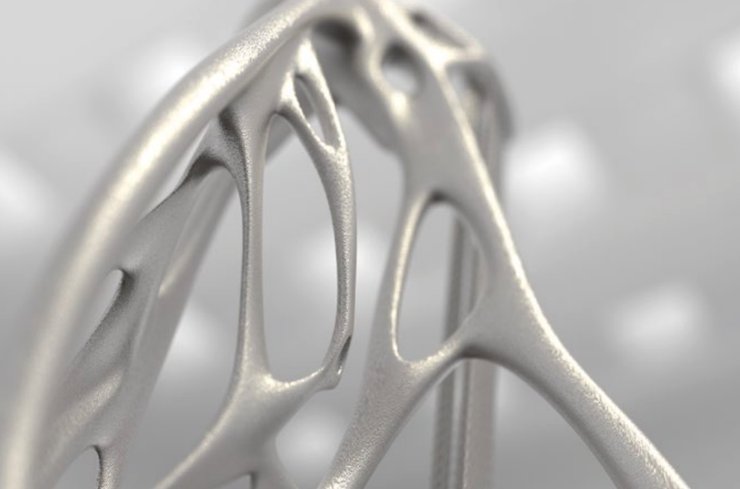

The big takeaway is Free Float’s ability to do away with support structures, a necessary feature of most 3D printing processes but one that can lead to time-consuming pre- and post-processing steps, increased material usage and limit design possibilities. With Free Float, SLM says AM users can now benefit from higher productivity, previously unachievable designs, reduced post-processing times, materials savings and the ability to pack more parts into a single build.

In a teaser last week, SLM Solutions CEO Sam O'Leary described the technology as "another milestone, not only for us but for the entire industry."

According to SLM Solutions, the technology was discovered as part of another research project which led to a breakthrough back in 2017. It works by selecting a standard .slm file which is then loaded into SLM’s software suite where users can apply a range of Free Float profiles depending on the application to enable different levels of improved surface finish, overall part quality and reduction of supports.

While other support-free technologies do already exist on the market from companies like Velo3D, SLM Solutions says its technology differs thanks to a ‘unique vector technology’ which ‘establishes thermal management that significantly decreases net build time while simultaneously enhancing part quality.’

Free Float can be retrofitted to almost any machine from the German metal AM provider’s current line-up, including the recently introduced NXG XII 600 12-laser metal 3D printer. What’s more, the company is offering the technology for free to existing customers via a Basic Subscription offering.

More information to follow.