Toolcraft, manufacturer of precision parts, assemblies, moulds and injection moulded parts, has expanded its machinery in order to more effectively meet the requirements of customers by investing in an M2 cusing multilaser system by Concept Laser.

The future of metal laser melting

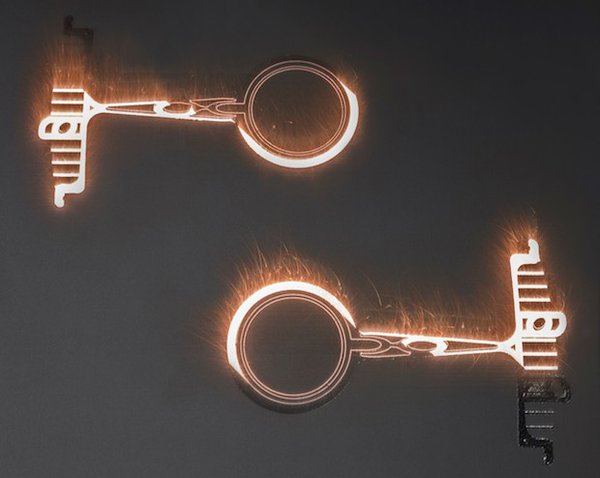

This latest addition increases Toolcraft's laser melting machine total to five and demonstrates how the company is looking to the future of metal laser melting. The machine has a workspace of 250 mm x 250 mm x 280 mm in the x, y and z directions. It can melt

down layers measuring 20-80 μm in thickness at a speed of 2-35 cm³/h depending on the material. The machine has an innovative laser system featuring two 400 W lasers which significantly increases the output compared to previous models. In addition, the M2 multilaser system offers the latest developments in process monitoring. The integrated system actually monitors the quality of the component during the manufacturing process.

Complete solutions from one source

The new unit produces precision parts made of nickel-based and titanium alloys, in addition to the new aluminium alloy Scalmalloy - a corrosion-resistant material with the specific strength of titanium at a simultaneously high ductility. As a partner for complete solutions, Toolcraft provides the entire process chain in-house, from design through to manufacturing and chipping "refinement" and quality testing. The final inspection and an optical measurement are performed exclusively by qualified staff. The quality of the components can also be quickly and reliably verified using a system for non-destructive surface testing.

Comprehensive quality assurance

The German manufacturer has recently expanded its portfolio in this field by investing in its own measurement and analysis technology which is used to check the powder quality and the properties of the molten material. Toolcraft meets the standard EN 9100 certification for aerospace applications which means the company has the capacity to manufacture housing components and complex, thin-walled structures for gas turbines. Certified precision parts for the medical technology sector are also produced in Georgensgmünd.