UnionTech has introduced its first four-laser, large-format SLA system at Formnext this week.

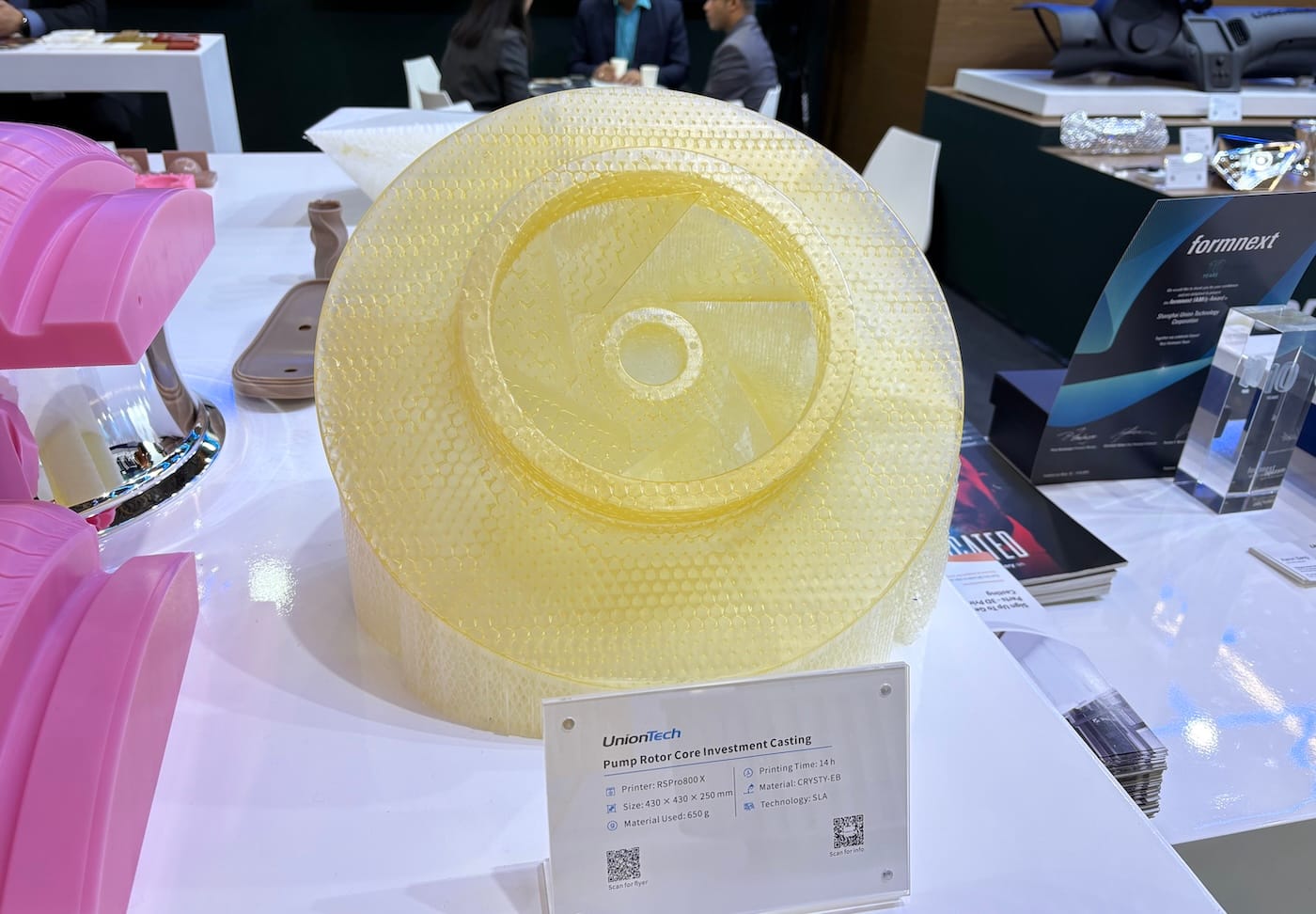

The Shanghai-based 3D printer manufacturer says the RSPro 800X can print 60% faster than its previous system, promising a "bigger, faster, cheaper” option for large-format prototyping, investment casting, and short-run end-use parts.

The RSPro 800X offers a build volume of 800 × 800 × 550 mm and a ±0.1 mm accuracy at 0.05 mm layer thickness.

On the booth, John Beckett, Managing Director at Europac3D, which represents UnionTech's products in the UK, explained how UnionTech has built the machine to deliver speed while maintaining part quality. Demonstrating with a full stack of eight highly complex and chunky parts, Beckett shared how three of the system's four independent solid-state Nd:YVO₄ lasers are assigned to build the infill, while one is designated to the part's contouring.

Each of those parts, according to Beckett, use around 3 kilos of material. On a regular RSPro800 system, that sort of build would take approximately 69 hours. On the new four-laser system, that reduces to 48 hours.

UnionTech is said to have developed the machine to overcome the limitation of being slowed down by the recoating process. A more powerful laser might cure the material faster, but you've still got to wait for that next pass of the recoater to keep building. By assigning three laser to build the bulk of the part, that time between recoating is said to have been improved massively.

While UnionTech is a China-based OEM, typically viewed as a cheaper option compared to Western machine makers, Beckett says many of the components inside the RSPro 800X have been built elsewhere. The lasers are said to be from a US manufacturer, the motors are Japanese, and the software is run by Siemens. So confident in its new hardware offering is UnionTech, the company is offering buyers at Formnext a six-month materials incentive - I'd recommend a visit to the booth to find out more.

UnionTech is also debuting its RSPro RA900 system for tyre mould production to the European market. The machine, which was initially introduced at TCT Asia earlier this year, is a dual-laser SLA printer with a substantial build volume of 950 x 550 x 400 mm, big enough for the simultaneous printing of four medium-sized tyre moulds.