Organisations across various industries face significant data management challenges. Receiving, converting, and interpreting an ever-growing volume of data, while ensuring that the right people have access to the correct data and meeting compliance requirements, is highly complex.

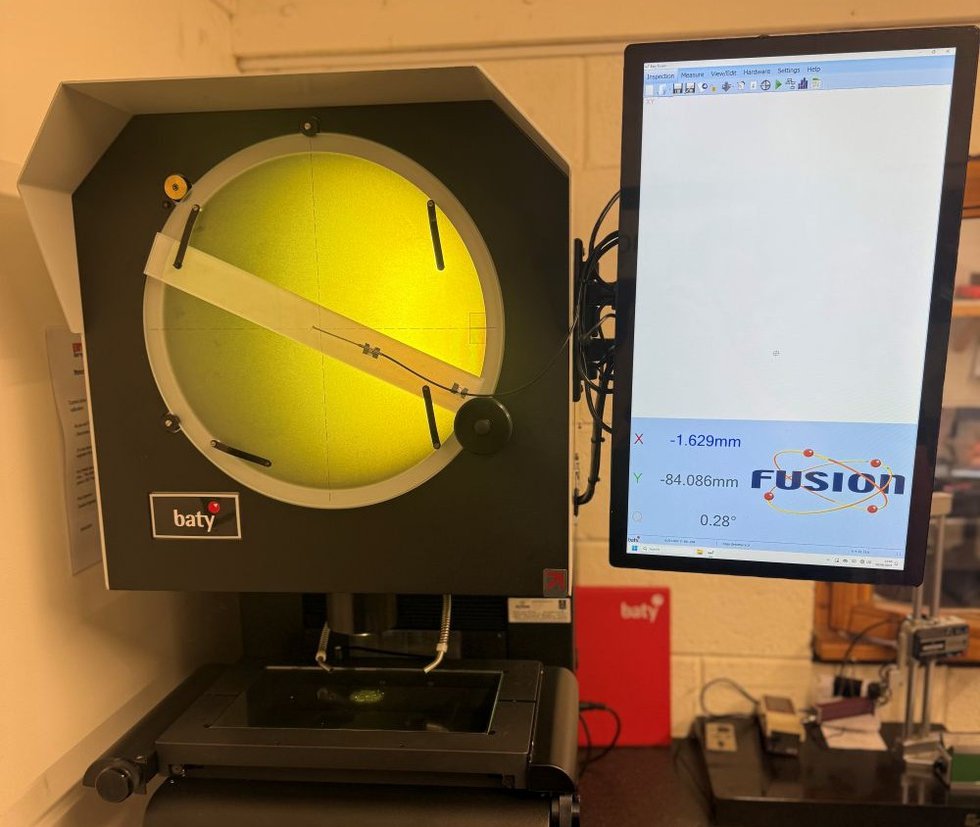

For QC leads and manufacturing engineers, it is essential to maintain high-quality standards and resolve production issues quickly. Technology must imperatively be kept up to date—relying on outdated practices such as transferring files via network drives or USB sticks is not only time-consuming and inefficient, but also prone to errors.

Data management software solutions like PolyWorks|DataLoop™ provide:

- Real-time access to inspection results

- Accelerated decision-making

- Simplified collaboration

- Streamlined workflows

Frédéric Hébert, Vice President of Products and Innovation for the Collaborative Suite, states, “By digitizing inspection project management, PolyWorks|DataLoop delivers optimal collaboration, security, and traceability—eliminating rework and promoting best practices across metrology teams and suppliers.”

GE Appliances: driving smarter data-driven decisions with PolyWorks|DataLoop

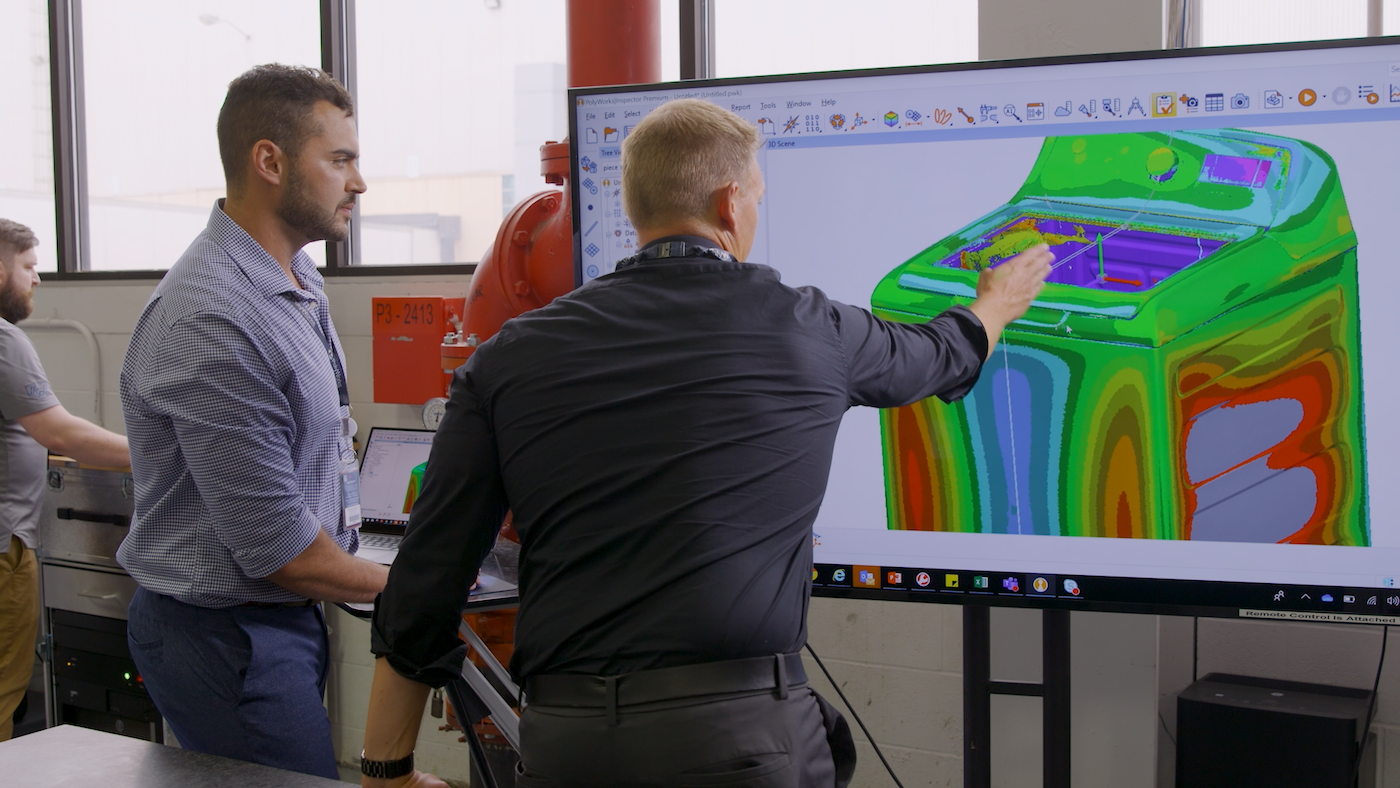

Facing the complexities of appliance manufacturing, GE Appliances adopted PolyWorks|DataLoop to make better data-driven decisions, boost quality and productivity, and manage 3D measurement data more efficiently, ensuring the right people promptly receive the correct data.

Founded in 1907, GE Appliances specializes in heating and cooking products. The company is known for innovations such as the first self-cleaning oven and over-the-range microwave.

Managing multiple product lines and hundreds of parts per product is exceptionally challenging, and the company needed to enhance both quality and productivity. To achieve this, GE Appliances concluded that standardizing software across multiple measuring devices, aggregating 3D metrology data, and delivering that data to engineers was crucial. As Dave Leone, Senior Director of Engineering and Dimensional Control, says, “All the 3D data in the world is not that valuable if engineers can’t get their hands on it.”

GE Appliances turned to PolyWorks|DataLoop to overcome their challenges. The solution handles vast volumes of data produced by multiple measuring sources and makes such data readily available to engineers and decision-makers.

PolyWorks|DataLoop enables teams to:

- Measure parts seamlessly

- Review results quickly

- Easily troubleshoot issues

- Adjust manufacturing processes simultaneously

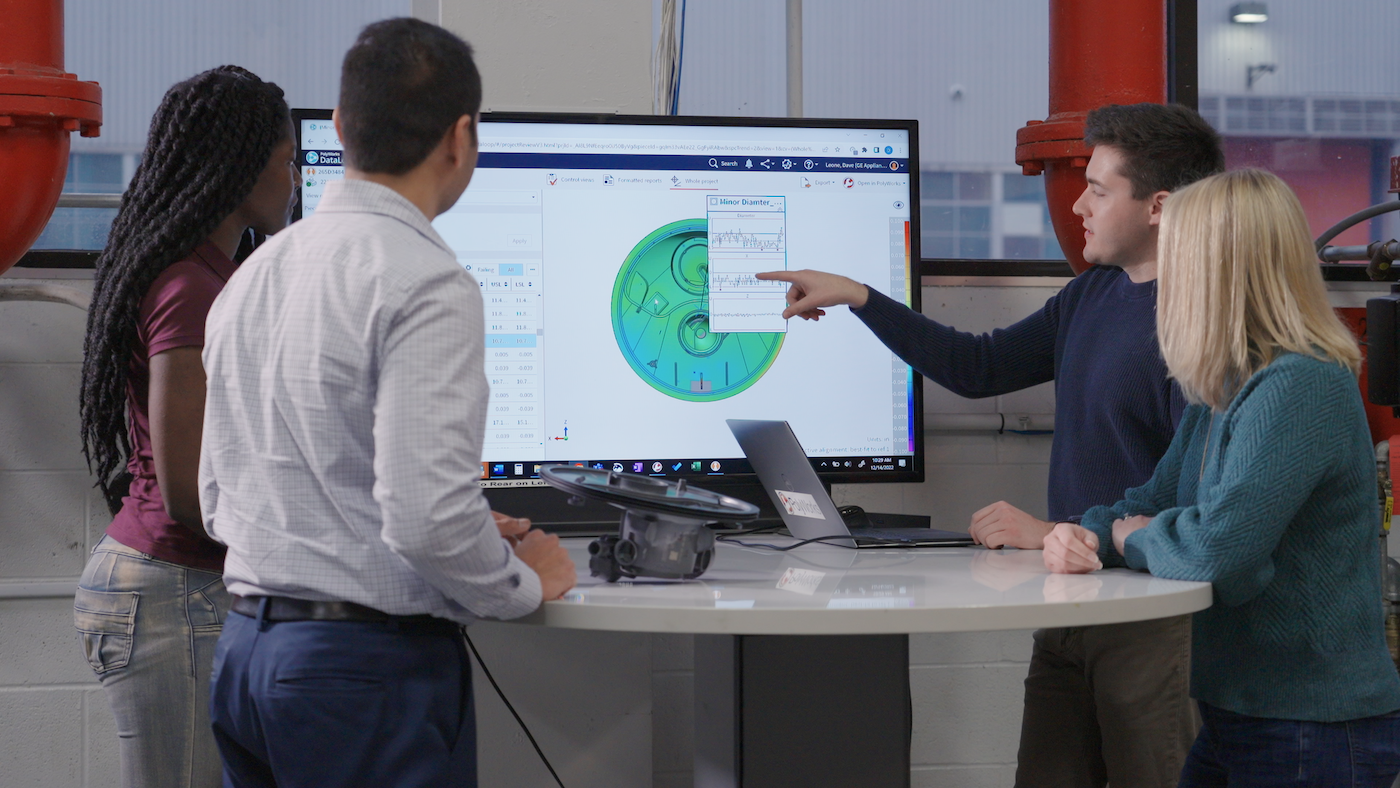

Hébert details how PolyWorks|DataLoop maintains quality standards while allowing multiple people to access the same data, explaining, “PolyWorks|DataLoop provides tools that make best practices easy to implement across all inspection projects. For instance, reusable piece and project templates for inspections, along with robust metadata management, ensure consistency and traceability. Lifecycle control tools guarantee that the right people have access to the right data at the right time. In addition, PolyWorks|DataLoop offers monitoring and alerts that safeguard the integrity of metrology data.”

Allowing multiple individuals to access data can pose a security risk. Regarding the solution’s flexible security policy, Hébert specifies, “Permission profiles can be defined for the wide variety of data managed within PolyWorks|DataLoop, ensuring each user accesses only what they need. These controls leverage state-of-the-art authentication technologies that follow best practices in cybersecurity governance.”

Key features of PolyWorks|DataLoop:

- Provides centralized storage for 3D measurement data

- Tailors the hardware setup to your business needs

- Automates file and folder management

- Maximizes data transfer speed

- Optimizes disk space usage

Q&A

Frédéric Hébert explains why engineers and QC leads should choose PolyWorks|DataLoop

RT: Why should QC leads and engineers invest in PolyWorks|DataLoop over alternative solutions?

FH: QC leads and manufacturing engineers should choose PolyWorks|DataLoop because it is the key enabler of the digital metrology lab. By digitizing inspection project management, PolyWorks|DataLoop ensures optimal collaboration, security, and traceability—eliminating rework and promoting best practices across metrology teams and suppliers. The PolyWorks|DataLoop Web Interface is intuitive and requires no deployment, making adoption seamless. Finally, its openness truly sets it apart: with robust APIs, connectors like those we developed for Microsoft Excel and Power BI, and PLM integrations, PolyWorks|DataLoop delivers a flexible data management system that integrates smoothly into modern digital ecosystems.

RT: If you could name one overarching benefit that QC leads and engineers receive from PolyWorks|DataLoop, what would it be?

FH: Empowerment through a true digital thread for 3D measurement processes—transforming raw metrology data into actionable insight. With PolyWorks|DataLoop, QC leads and manufacturing engineers gain secure, seamless access to the right data at the right time, collaborate effortlessly across teams and hardware, and unlock the full potential of their measurement ecosystem to drive quality, efficiency, and innovation.