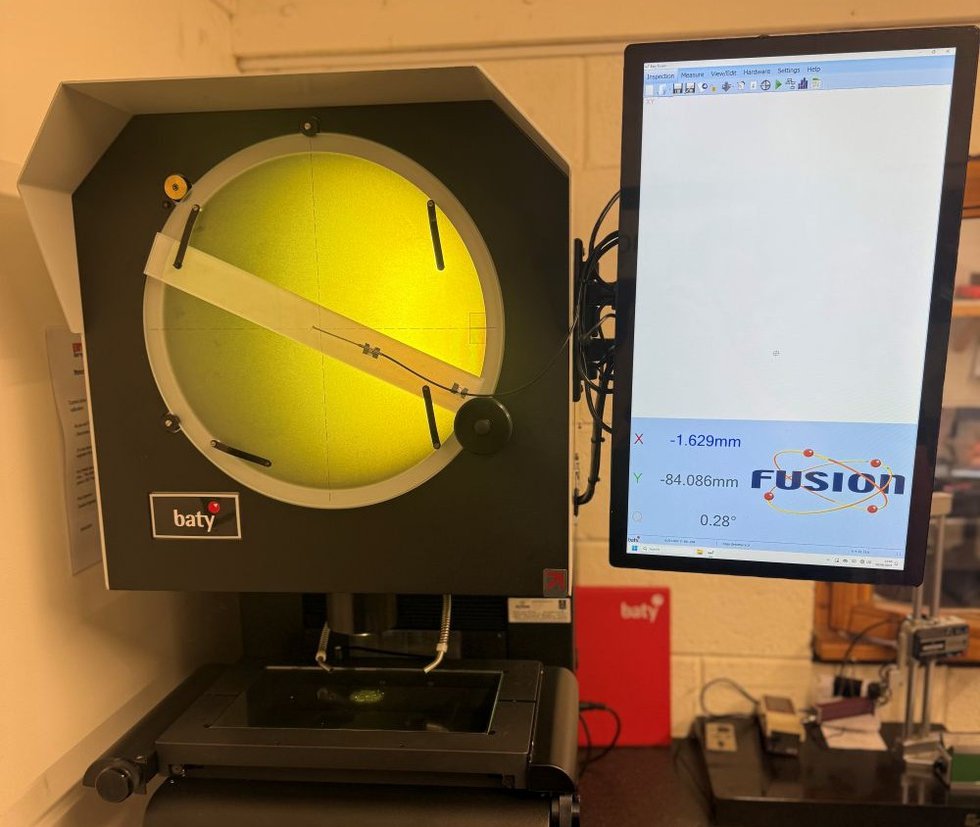

Yorkshire Precision Engineering Ltd (YPEL) has boosted its inspection capabilities by investing in a new Baty SM350 shadowgraph with FT2E. Supplied by Bowers Group, the adopted solution is expected to provide YPEL with improved accuracy, reduced inspection times, and enhanced reliability across its operations.

Founded by their parents, YPEL is today managed by Sam and Jack Laybourne and has grown into a trusted supplier of precision-turned and milled components for various industries, including agriculture, automotive, brewing, food, oil and gas, and medical.

“If you come to us, it will be right,” said Sam Laybourne, Managing Director of YPEL. “That’s how we’ve earned our reputation and why customers keep coming back to us after more than 20 years. Our entire business is built on quality, both in the product we deliver and in the way we communicate with customers.”

For over a decade, YPEL used the Baty SM300 shadowgraph for inspection. Recently, the limitations of the ageing machine started to show. With the screen becoming less clear, it was harder to guarantee accuracy levels. This reduced clarity increased the risk for human error, and inspections were taking longer, slowing down production and reducing efficiency.

To solve this developing issue, YPEL invested in a new Baty SM350. This new machine provides the company with edge detection technology that eliminates operator subjectivity, a sharper and clearer screen, and an interactive touchscreen that makes dimension capture easier and faster.

The SM350 is used to:

- Check turned and milled profiles.

- Measure thread forms and angles.

- Verify chamfer and countersink sizes.

- Assess the concentricity of components.

The solution is also invaluable when inspecting medical components, allowing YPEL to ensure internal holes are free from burrs or foreign bodies. Following the adoption, Sam estimates that inspections are now carried out 40% (approximately) faster than before.

“The clarity of the SM350 machine has been welcomed by all of our engineers and has sped up inspecting our parts, meaning the engineers can focus on keeping the machines running, making us more profitable,” he said. “The edge detection has eliminated human error, inspections are quicker and more reliable, and we’ve seen huge time savings.”

He continued, “The shadowgraph and software are both very user-friendly, and the engineer who came to set it up was extremely knowledgeable. Because we already use Aberlink CMMs, there were a lot of transferable skills, so training was straightforward. The touchscreen is brilliant, pulling dimensions off is so much easier and more interactive. Overall, we couldn’t be happier with the upgrade.”

Sam concluded, “Bowers are a fellow BTMA member, and it was an absolute pleasure to work with them. It’s also fantastic to know their products are manufactured here in the UK. We’re very happy with our new shadowgraph, and it’s already proving to be an essential part of our inspection process.”