Mantle has introduced a new software update that enables mould features up to 80% thinner than the company's TrueShape metal 3D printing technology was previously capable of.

Top Definition, which has been made available via an over-the-air software release, will allow users to directly print features as thin as 0.2mm, while 'dramatically improving' the as-printed strength of small features that were previously too fragile to print.

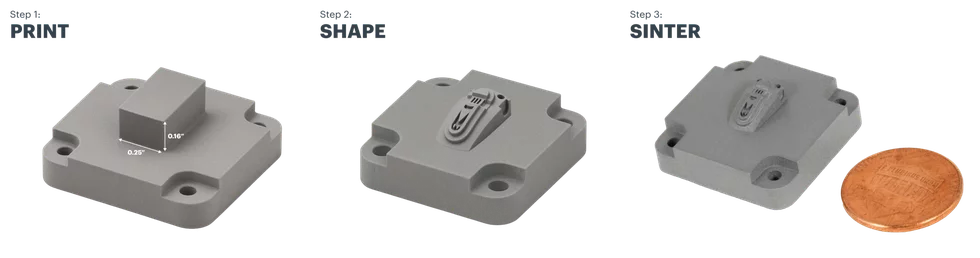

The Top Definition process is said to differ from Mantle's standard layer-by-layer printing and machining approach, with the new method printing a solid block of material at the top portion of the tool before a top-down machining process provides structural support for details much smaller than Mantle’s standard layer-by-layer print and machining can support. Wall thicknesses can now be produced at sizes of 0.2mm and pins can be produced at 0.6mm.

According to Mantle, the Top Definition software update comes amid 'growing demand for domestic tooling solutions' in North America, with the company reporting that bookings through mid-2025 have 'increased twofold compared to the same timeframe in 2024.' Among those to have deployed Mantle'S TrueShape technology are Conesys, American Tool & Mold, International Precision Mold, a Bankier Company, P1 Technologies, and Seaway Plastics. Conesys has installed multiple systems.

"For more than 10 years, I've been searching for a 3D printing technology robust enough for production moulds. After validating Mantle's technology and experiencing its unmatched precision, we've integrated multiple Mantle printers into our operations," Mark Edwards, Chief Information Officer at Conesys. "We're now reducing the time and cost associated with producing new tooling, allowing us to respond to our customers more quickly and bring new products to market. The adoption of Mantle's new Top Definition capabilities will further enhance precision, driving even greater efficiency and throughput within Conesys's toolroom."

Earlier this year, another software update increased production throughput of Mantle's TrueShape technology by up to 20%.

Additive Insight by TCT · #203 Mantle CEO Ted Sorom: 'We’re trying to build a business, not just an interesting technology.'