UltiMaker is reinforcing its commitment to serving the defence sector with a new Secure Line of desktop 3D printers, designed around the requirements of high-security environments.

Built to be used as a "deployable tactical asset", per UltiMaker's announcement, the new machines take a more ruggedised form, and are stripped of features that can open systems up to threats of espionage, data theft, or remote intrusion. That means no Wi-Fi, no external cameras, and no unverified third-party devices. Instead, these features have been replaced with factory-flashed, tamper-resistant firmware, encrypted and auditable file handling, and hardware-sealed components, complete with Loctite screws.

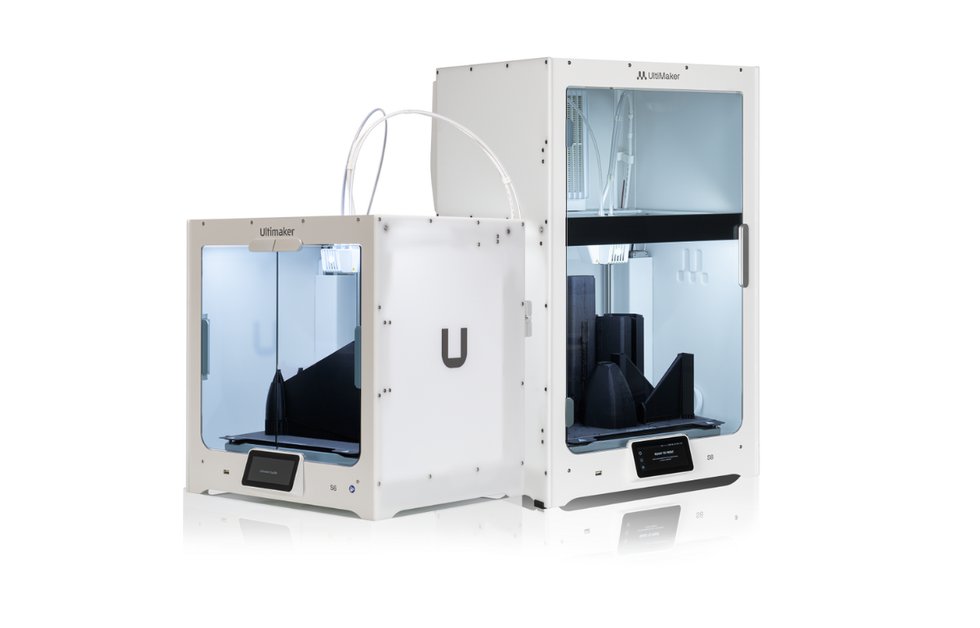

Following on from the launch of the UltiMaker S6 in June, which Andy Middleton, SVP EMEA and Global Marketing at UltiMaker described to TCT as making the company's hardware offering "even more bulletproof than before", the Secure Line applies to both the UltiMaker S6 and S8 models. The UltiMaker S6 Secure and UltiMaker S8 Secure machines will adopt the same UltiMaker Cheetah motion planner, high flow print cores, and an improved feeder system, with four times the productivity of the UltiMaker S5. They also come with a two-year UltiMakerCare service warranty.

In a press release, Middleton said the new line "represents a strategic leap in making additive manufacturing a trusted and deployable asset for defence organisations." The company says its machines have a history of being used by NATO-aligned organisations, and the new systems are being manufactured in the Netherlands under European standards for quality, data security, and compliance, in limited batches, tailored to the specific requirements of defence users. UltiMaker says broad availability of the Secure Line "for qualified defence and aerospace organisations" will begin immediately.

“With Secure Line, we give defence organisations something they have not had before: industrial 3D printers they can fully trust anywhere in the world,” said Arjen Dirks, CTO at UltiMaker. “We designed our Secure Line products with security built into every layer and to meet internationally recognised standards, combining reproducibility and long-term reliability in a form that guarantees tactical capability in defence environments.”

In the battle for desktop 3D printing dominance, particularly against the rise and popularity of lower cost machines from Chinese manufacturers, security, it seems, is UltiMaker’s biggest mode of defence.

Jim Franz, President Americas at UltiMaker, told TCT, "We want to press the security issue and make it easy for organisations to be able to incorporate this into their workflows without having to jump through hoops to get it installed and bring more awareness about the potential security issues that are out there in the field, that people don't even realise."

The S6 and S8 Secure have been built with feedback from defence customers who are reportedly using UltiMaker hardware for applications like maintenance jigs and fixtures and end-use part such as firearm adaptations for comfort, antennas, and filters.

"Here in the US, we are working through one of our partners who have our products listed on GSA," Franz said. "We were also talking very closely with the Dutch Navy and the Dutch Army about what their requirements are. So we're really taking input from both places across the pond, and trying to get the stuff that they need in order to get our systems incorporated into their workflows."

UltiMaker is really making a big swing for defence. The Royal Netherlands Navy is deploying UltiMaker S series 3D printers to produce spare parts on-demand, and the Dutch Air Force is using UltiMaker machines to create custom tools to maintain its fleet of helicopters, fighter jets, and cargo planes.

"We really want to build that presence up," Franz added. "And I think the secure line can really help us do that."