The University Hospital Birmingham is using Stratasys’ J5 MediJet 3D printing system to produce tailored cutting guides for head and neck cancer patients.

With the use of 3D printed cutting guides, the University Hospital Birmingham is said to have reduced surgery times by up to three hours.

These 3D printed cutting guides have ‘transformed’ the way tumours are removed from head and neck cancer patients, with doctors previously having to cut and bend pieces of metal by hand while the patient was on the operating table.

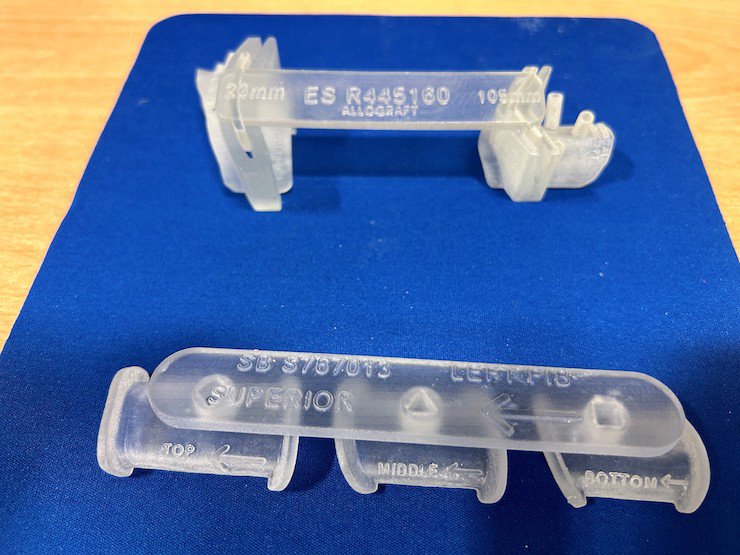

Now, surgeons can use 3D printing to produce highly accurate devices that leverage data from patient scans. Printed in Biocompatible Clear MED610, a rigid and transparent resin suitable for application that require long-term contact (more than 30 days) with intact skin and limited contact (up to 24 hours) with tissue, bone, or mucosal membranes.

The J5 MediJet was launched in 2021 to give users the ability to create multi-material, full-colour parts in an office or lab environment. University Hospital Birmingham acquired its J5 MediJet through UK reseller Tri-Tech 3D, and has since recorded significant time reductions and enhanced patient care. Integrating 3D printing technology has allowed surgeons to better prepare complex surgeries, and also communicate the procedures to patients.

“In addition to saving up to three hours of surgery time, 3D printing also enables much better surgical planning,” commented Stefan Edmondson, Consultant Clinical Scientist (Reconstructive Science) at University Birmingham Hospital. “Using patient scans, the team is able to create 3D visualisations based on the distinct anatomy of each patient – and then leverage 3D printing technology to produce both anatomical models and personalized surgical cutting guides ahead of the actual operation.

“This capability means we can not only accurately predict the surgery before it’s done, but that we have the tools to ensure that the meticulous pre-surgical planning can be executed with the utmost precision. The surgical team is also much better prepared and the patient is far more at ease, as we can talk through the process and expected outcomes prior to going into the operating theatre.”