1 of 2

Via YouTube

Local Motors 3D Printed Car

2 of 2

Adapting Strati Body to 3D Printed Car Prototype

The design for Local Motors' first 3D-printed car has been selected by the open-source automotive design and manufacturing company.

More than 200 designs were submitted to the Phoenix-headquartered business in a competition tasking designers to come up with an innovative framework for a ground-breaking electric vehicle to be additive manufactured.

After much deliberation, Michele Anoè's 'Strati' stood out as the design Local Motors was looking for, however aspects of 'Internal Strut Frame' by Greg Thompson, the runner-up and winner of the community vote, could also be used in the final iteration, which will be 3D printed, finished and assembled over the six days of the International Manufacturing Technology Show in Chicago in September 2014.

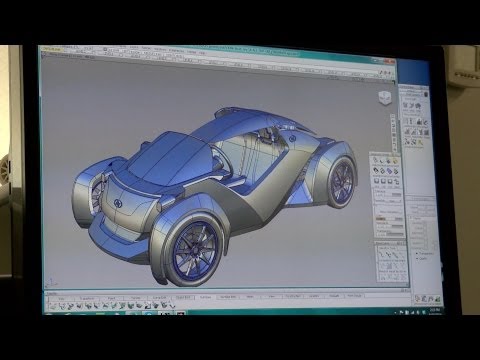

Local Motors Design Engineer Nestor Llanos has been sharing the process of adapting 'Strati' into the design for the final 3D-printed product via Local Motors' blog.

"We have a final styling for the car, it’s a really nice entry with really nice digital data. The model that [Michele Anoè] gives us is really nice work and basically what we need to do is apply this styling to all the components that we are already working on with the prototype," Llanos explained.

He noted that he is using software both from Dassault Systèmes and Autodesk to bring the designs on the screen to life, while preparing Strati for 3D printing. He noted that the '45 rule' is being applied to reduce the amount of support material needed to build the car.

The Direct Digital Manufacturing Project (DDM) is exploring how hybrid additive and subtractive manufacturing systems developed by Oak Ridge National Labs can be used to build cars. The aim of the initiative is to build much of a car and to demonstrate how these advanced manufacturing techniques could be more efficient and effective than traditional automotive design and engineering techniques.