1 of 2

Cervical cancer cells

2 of 2

3D Printing of Multi-Material Scaffold by Additive Manufacturing

Fabrication of 3-dimensional multi-material scaffold by additive manufacturing; specifically Drexel University Biofabrication Lab's bioprinter. Bioprinter's sub-systems include 3-dimensional motion system and multi-nozzle deposition system controlled via CAM software.

Doctors in China and the US have used 3D printing to successfully create a replica 3D model of a cancerous tumour.

The research, published in the medical journal Biofabrication, has led to the creation of a realistic model of a tumour's environment and could aid in the discovery of new drugs and further enhance the medical profession's understanding of how tumours grow and spread throughout the body.

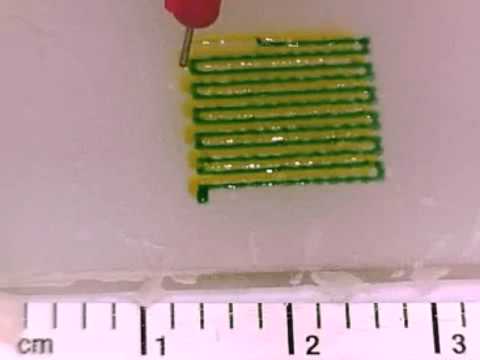

Results of the test indicate the 3D model bore more of a similarity to the environment in which a tumour grows than previous attempts. It featured a scaffold-like structure of fibrous proteins coated in cervical cancer cells. It consisted of a 10 mm sq grid structure made from gelatine, alginate and fibrin, recreating the fibrous proteins that make up the extracellular structure of a tumour. Within this framework was a coating of Hela cells derived from a cervical cancer patient back in 1951 that are considered unique for their 'immortal' regeneration capabilities. The cells' ability of divide indefinitely in laboratory conditions has meant they have been used in some of the most important cancer research projects in the last half-century.

The most effective way of investigating tumours is via clinical trial, but the ethical and safety issues of doing this make it difficult for research projects such as this to be carried out on a broad scale. Therefore, 2D models had been used in the past to mimic the physiological environment of tumours, but with the advent of 3D printing, medical professionals can now conduct their work using a more realistic replica of the environment surrounding a tumour.

Lead author of the research professor Wei Sun, from Tsinhua University in China and Drexel University in the US, commented: "We have provided a scalable and versatile 3D cancer model that shows a greater resemblance to natural cancer than 2D cultured cancer cells.

"With further understanding of these 3D models, we can use them to study the development, invasion, metastasis and treatment of cancer using specific cancer cells from patients. We can also use these models to test the efficacy and safety of new cancer treatment therapies and new cancer drugs."

After 3D printing the model, the researchers tested the viability of the cells, as well as if they were still alive - 90 per cent of the cancer cells were viable post-3D printing in this research. The team then looked at how the cells proliferated, expressed certain proteins and how resistant they were to anti-cancer treatments.

The proteins that were under the microscope are part of a family of chemicals used by cancer cells to break through their surrounding matrix, enabling tumours to metastasise. The study of resistance to anti-cancer drugs also indicated tumour malignancy.

The more accurate 3D model also yielded results indicating a higher rate of proliferation, higher protein expression and higher resistance to anti-cancer drugs.

3D printing is being used to support medical treatments around the world, with UMC Utrecht reporting in March that a young Dutch woman with a rare and potentially fatal bone thickening disease had a significant amount of her cranium replaced with a 3D-printed prosthetic. Earlier in the year, Transparency Market Research published a research paper indicating the progress of 3D printing in the medical sector - a major growth area for the industry.

To read Wei Sun's research online click here.